Materialise has just launched a superior consumer-grade finish ideal for wearables, available in fifteen contemporary colours. It will make “the difference between a print and a product”, Materialise claims.

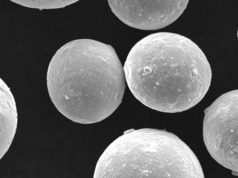

The new Luxura finish is designed to deliver the ideal aesthetics, tactile feel and quality assurance that wearable products require. It has a silk-like surface smoothness with in-depth color permeation, and offers the necessary performance characteristics – durable, skin-contact safe, perspiration-proof, UV-resistant – that a wearable product requires.

Materialise developed the finish in response to increasing interest from the eyewear and wearables sectors to create additive manufactured solutions that stood up to the high aesthetic and performance standards these industries demand. Luxura is for brands and designers that have a desire to take advantage of the design freedom and mass customisation opportunities of 3D printing for their wearable solutions and create a product with a premium look and feel. Luxura can also be colour matched on request for those brands looking for something truly unique.

Commenting on the new finish, Alireza Parandian, Business Developer, Materialise: “We understand that when creating consumer products the look and feel is of absolute priority. It needs to attract attention and draw the consumer, reflecting the high-end quality of the brand. With Luxura we have created a finish that engages the senses and can stand out in the competitive landscape of wearables and consumer products”.

Materialise worked with consumer brand partners, to develop Luxura to ensure that the end-result reflected the quality of their brands, and gave them a solution they could take to market. Parandian continued: “There is a perception with 3D printing that the finished products cannot compete with products made via traditional manufacturing methods and materials. We have worked hard to dispel this view, and demonstrate how, through collaboration, we can deliver solutions that blend the traditional craftsmanship approach with the cutting-edge innovation of 3D printing to make desirable products.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.