3D Hubs has just added a new material group to their 3D print service consisting of a network of nearly 30,000 hubs worldwide: Kevlar, Carbon & Fibreglass.

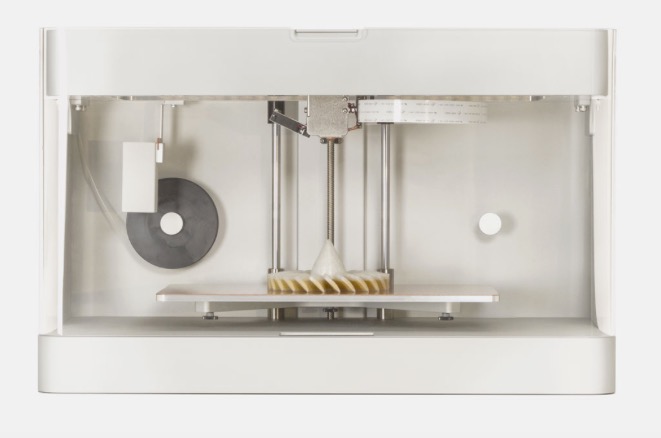

The printers capable of producing nylon sturctures with embedded strands of fibre are manufactured by Markforged. The latest model is the Mark Two 3D printer. It uses two print heads: one that builds the nylon part and the other reinforces the part with continuous fibre.

Produced parts have a higher strength-to-weight ration than 6061-T6 Aluminium and are up to 27 times stiffer and 24 times stronger than ABS. While the material is less suitable for small, detailed parts it is ideal for mechanical and engineering parts such as jigs, fixtures and tools.

Among the three different materials, Carbon-reinforced nylon has the highest strength to weight ratio and the highest thermal conductivity. Fibreglass-reinforced nylon on the other hand has the lowest cost. While being as strong as carbon fibre, it is 60% less stiff and two times heavier. Kevlar-reinforced nylon features the best abrasion resistance and ist the most flexible of the three. It is ideal for parts that need to be durable and resistant to impact.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.