How we made a 3D Printed Marble Machine using our TO-BE LAUNCHED Indie: The Desktop 3D Printer.

This is a 3D Printed marble machine on our latest Indie 3D Printer that takes marbles through crazy loops and turns. A marble machine designed in ONSHAPE is completely based on rigid bodies, rigid body joints and mechanics. The assembly has approximately 34 parts printed in ABS , and it can be powered by using DC motors or batteries. It uses a 1.5 cm diameter steel marble, which starts at the bottom, and goes to the top, and then returns to the bottom, making this trip about 8640 times in 24 hours.

At first glance, it may look relatively simple, but a lot of planning and tweaking had to go into the design process keeping in mind that all parts have to be 3D Printed and support free to avoid any kind of post processing. It took us approximately 2-3 weeks to design the assembly on Onshape and a series of iterations to make a working model of the marble machine. The STL are available for free on Thingiverse.

The working of the marble machine is mesmerizing to one’s eye.

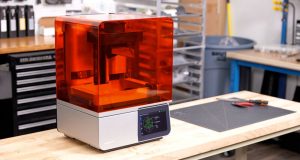

The Mumbai-based 3D printer manufacturer will be launching the Indie Desktop on popular crowdfunding site Indiegogo (say that three times fast!) in the next month. The company is also currently taking sign-ups for early bird access to Indie Desktop, which will be available for 50% off the actual price. So if you sign up now, you’ll only pay $549!

Here are some of the features of the Indie Desktop:

- Enclosed heated chamber and bed, which allows you to print large parts with very limited warping and cracking

- A large print bed size of 8 x 8 x 7.5 inches

- Enclosed filament storage; you can also monitor your filament motion and trigger a ‘pause’ signal to the printer before your parts are ruined

- LCD display

- Plug and play with pre-installed extruder

- Uses open source software Cura

- Optional Wi-Fi module, so you can 3D print your designs with a Raspberry Pi and OctoPrint

- Low cost; by using composite materials, injection molded parts, and a thermoformed ABS chassis, the printer’s manufacturing cost is low.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.