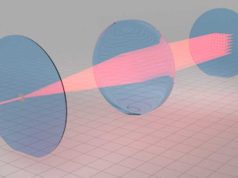

Researchers of the University of Stuttgart and the Stuttgart Research Center for Photonics Engineering 3D printed very small optical elements that could change the size of sensors and cameras.

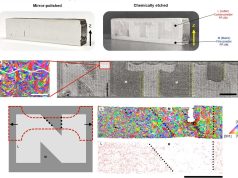

The researchers used a femtosecond laser and the two photon polymerisation. Two very short (less than 100 femtoseconds) pulses of red laser (785nm) are fired onto an liquid polymer. Exactly where these photons hit each other the material hardens.

With this technology it was possible to produce optical lenses with individual optics. These micro-objectives are just as big as 100µm (120µm with housing) and can be printed on glass surfaces, fibre optics and also directly on CMOS-Chips.

“The time from the idea, the optics design, a CAD model, to the finished, 3D printed micro-objectives is going to be less than a day”, states Professor Harald Giessen. “We are going to open potentials just like computer-aided design and computer-integrated manufacturing did in mechanical engineering a few years ago”.

This development could lead to small sensors and cameras or even LED lights the size of insects. The researchers think that this could be used in micro drones the size of a bee.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.