In March, the Relativity Space Terran 1 rocket launched from Cape Canaveral Space Force Station in Florida. This was the first launch of a test rocket made entirely from 3D-printed parts. In doing so, the design team relied on an alloy developed by NASA.

This copper alloy, developed at NASA’s Glenn Research Center, is optimized for high strength, thermal conductivity and creep resistance. It can withstand 40% higher temperatures than conventional copper alloys, resulting in higher-performance, reusable components.

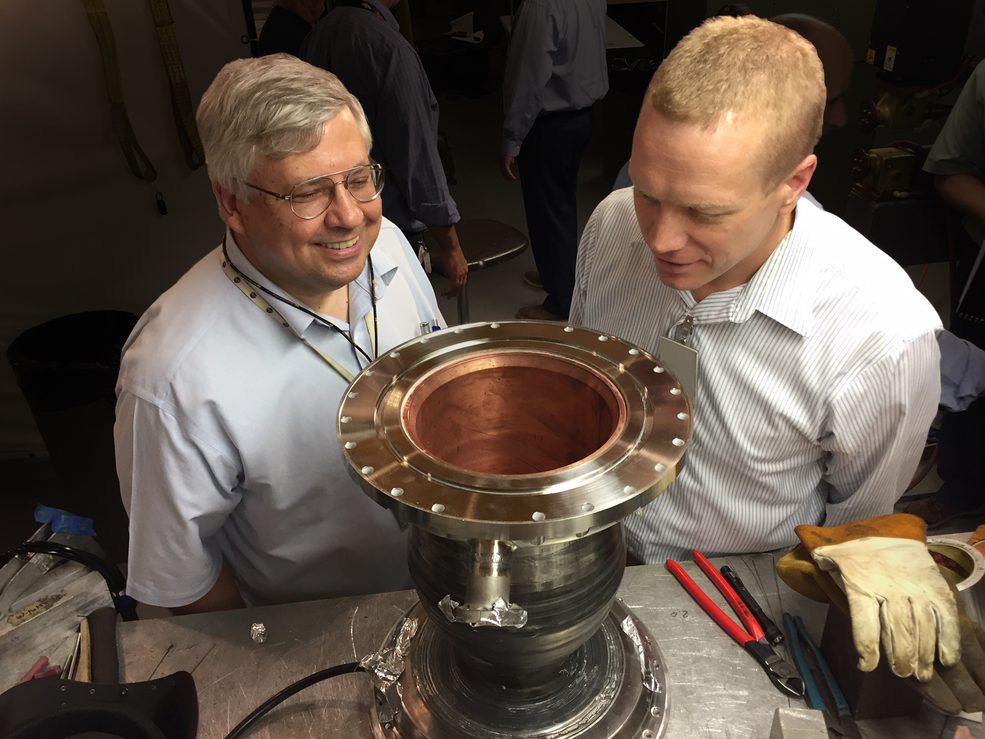

Dr. David Ellis, a doctoral student during the space shuttle era, developed the GRCop alloy.

“At the time, Space Shuttle Main Engine combustion chamber liners were typically replaced after one to five missions,” explained Ellis. “Our research was able to show that GRCop-84 would easily meet the goal of 100 missions between maintenance service and 500 missions of engine life.”

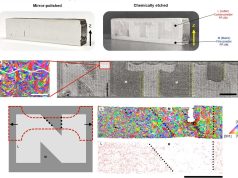

The current version, GRCop-42, uses additive manufacturing techniques to produce combustion chambers and thrust chambers for rocket engines. These techniques improve performance and reduce weight and cost.

Advanced manufacturing techniques such as laser powder bed and directed energy deposition are used to produce GRCop parts. Both processes build on layered technology, achieving material strength comparable to forged metal.

“Development projects, like RAMPT, allow advancement of new alloys and processes for use by commercial space, industry, and academia,” said Paul Gradl, principal engineer at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “NASA takes on the development risk and matures the process from early material and process concepts through certification. This infusion of GRCop-42 alloys into commercial space is another great example of how NASA-led innovations advance industry capabilities and contribute to America’s growing space economy.”

NASA provided technical support to Relativity Space to make GRCop-42 a flight-ready product. These more powerful rocket engine components could be used on future missions to the moon, Mars and beyond.

Find out more about Relativity Space at relativityspace.com.

For more information about Nasa, please visit nasa.gov.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.