The disposal of stone waste from quarries can be a major challenge. In Ticino, Switzerland, this rock flour can account for up to 40% of total production. To address this problem, the Swiss Federal Institute of Technology Zurich (ETH) and the University of Applied Sciences of Southern Switzerland (SUPSI) have developed a 3D printer that produces customizable architectural elements from waste.

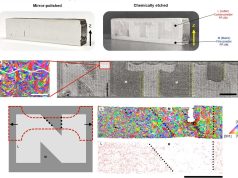

A case study demonstrates the use of this 3D printing process to produce an optimized floor system. A structurally optimized funicular floor assembly was created from waste material from a marble quarry in Ticino. The project illustrates how 3D printing complex structural shapes can reduce material consumption and promote the use of local, recycled resources.

In its current form, however, BJT is unsuitable for construction: The printed parts are brittle. The organic binders have poor fire and weather resistance and continue to emit volatile organic compounds for several weeks after manufacture.

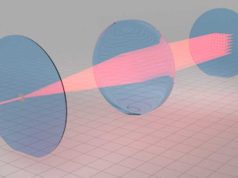

The technology uses binder jetting (BJT), a 3D printing process that uses a binder to solidify specific areas of the granular material layer by layer. ETH Zurich developed a method that proposes an alternative geopolymer-based binder to overcome the common limitations of BJT.

The combination of recycled materials and 3D printing methods is particularly suitable for pressure-dominated systems that maximize compressive strength. The assembly will be exhibited at Palazzo Mora during the 2023 Venice Architecture Biennale.

Find out more about ETH Zürich at ethz.ch.

For more information about the University of Applied Sciences of Southern Switzerland, please visit supsi.ch.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.