B2B Manufacturing SaaS Startup 3D Spark closed its first funding round and secured growth opportunities as well as planning security for its customers for the next 2 years. The funds will be invested in strengthening the team’s personnel, to further accelerate the development of the 3D Spark platform and expand customer support to ensure an excellent industrial-standard service offering.

Every manufacturing company is looking for the cheapest, fastest, and most sustainable solution to produce components, otherwise it risks wasting money, time, material and energy and being left behind by market competitors. However, identifying the most appropriate process for each part requires immense process technology know-how and lengthy manual analysis.

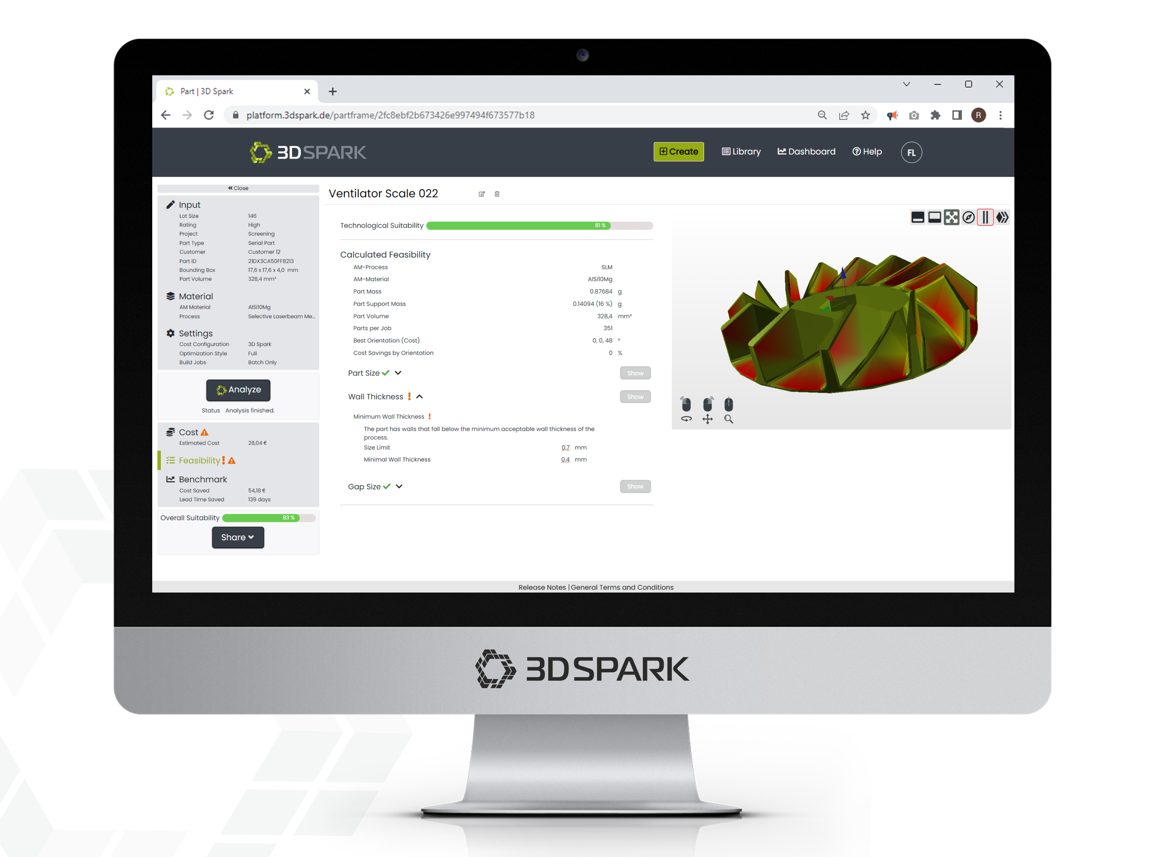

The 3D Spark software automates this identification, comparable to a “comparison engine for components”. Based on 3D CADs, 2D drawings and metadata, it identifies the cheapest, fastest and most sustainable manufacturing process for each component, currently focusing on industrial 3D printing. In this way, the software supports industrial employees worldwide in making smarter production decisions, thereby making a measurable contribution to more sustainable, crisis-resistant, and efficient production.

Long-term planning security guaranteed for industrial customers

“We are very pleased with the trust placed in us by IFH and FTTF and the associated attractiveness of the name “Fraunhofer” and the city of Hamburg. For our customers, we want not only to offer the most innovative solutions, but also to be a stable and reliable partner that offers long-term planning security. This capital increase ensures exactly that, so that potential customers can now enter into a partnership with us with good conscience.” States Ruben Meuth (Co-CEO and Co-Founder).

“3D Spark’s software not only enables customers to quickly decide whether 3D printing processes are a good fit, but also provides a general comparison with conventional processes. As 3D printing processes become more efficient and affordable, this technology becomes more relevant for mass-produced products as well. The 3D Spark team convinced us with their excellent, technological know-how and their well-known reference customers.” Dörte Bunge from Innovationsstarter Fonds Hamburg comments.

“We have known and observed the founding team for quite a long time. We were impressed by the continuous and structured development of the technology and the business model, which led to the company being able to sell software licenses to renowned customers already in this early stage of the company – delivering high and measurable customer benefits. Thus, we see 3D Spark on a very good path towards an excellent “product-market-fit”.” Jörg Wamser from the Fraunhofer Technology Transfer

Fund (FTTF) explains.

Manufacturing service providers and OEMs benefit from substantial savings OEMs such as Alstom and ZF are using 3D Spark to reduce production costs and delivery times while

increasing supply chain security and component performance. As a global specialist in smart and sustainable mobility solutions, Alstom has already saved more than €1.8 million in costs and 20,000 days in lead time with 3D-printed fixtures, spare parts and volume applications using 3D Spark software, and plans to save more than €5 million in 2023. Manufacturing service providers like MetShape analyze manufacturability for twelve 3D printing processes and calculate production costs in seconds, speeding up quoting many times over.

3D Spark dreams of a future without waste in manufacturing

“We dream of a manufacturing future without waste. Billions of components are produced worldwide every day – many with higher costs, delivery times, material and energy consumption and CO2 emissions than actually necessary. Manufacturing companies often simply lack the transparency needed to select the cheapest, fastest, safest, and most sustainable production process for each component. To create this transparency, we will continuously expand our technology portfolio beyond 3D printing processes and thus offer a comprehensive comparison for all relevant manufacturing processes,” says Dr.-Ing. Fritz Lange (Co-Founder & Co-CEO).

For more information about 3D Spark GmbH, please visit www.3dspark.de.

To learn more about Innovationsstarter Fonds Hamburg GmbH, please visit innovationsstarter.com.

To find out more about Fraunhofer Technologie-Transfer Fonds (FTTF), please visit fttf.vc.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.