3D4Makers released a long sought-after 3D printing material, manufactured from Zymergen Z2 polyimide for sampling. Polyimide is a very high-strength polymer that is inherently flame retardant, has excellent insulating properties and excellent thermal stability.

Zymergen uses machine learning, genomics, and automation to look for biomolecules that perform better than petroleum-based chemicals. In this way, Zymergen aims to make bioinspired materials that are more efficient and designed to displace petroleum-based materials. 3D4Makers’ filament is special because it utilizes Zymergen’s Z2 polyimide, which demonstrates low warp and easy to 3D print while having significant Z strength.

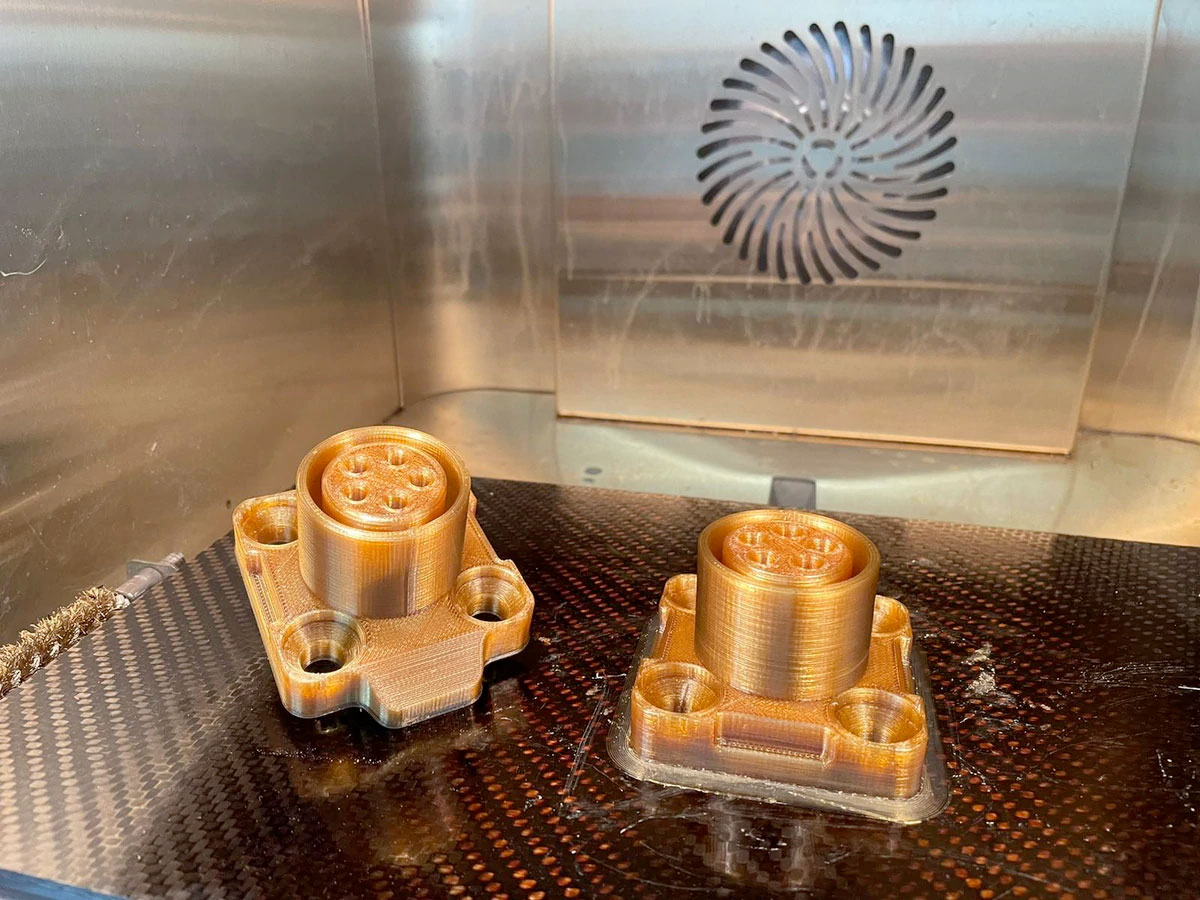

Zymergen and 3D4Makers have announced that they have signed an R&D Supply Agreement to make this breakthrough material available for sampling. The material has been extensively tested by high-temperature 3D printing manufacturers miniFactory, OrionAM, Aon3D, and others.

Adam Rumjahn, Managing Director of OrionAM said: “The ability to 3D print polyimide is a game-changer for the additive manufacturing industry. This material has the potential to out-perform high-performance polymers like PEEK, PPSU, and PEI in applications where high strength and high temperatures are required. We are at the brink of something new and exciting.”

3D4Makers co-founder Jasper Wille commented:”At 3D4Makers we have always taken pride in offering the highest performance 3D printing materials that the world has to offer. These materials have been used in aerospace, racing, and industry by leaders in their fields. These clients are always looking for the highest performance material that they can get. And one of the most requested materials has always been PI. Polyimide has excellent properties, but has always been difficult to 3D print. Now we are proud to have a printable polyimide that is sure to be used for a lot of cutting edge applications”

Olli Pihlajamäki COO at miniFactory said:” miniFactory has always sought to make industrial Material Extrusion of ultra performance polymers as reliable and repeatable as possible. With over six years of industrial 3D printing experience with PEEK, PEKK, PEI, and similar materials, we really understand what our clients need from 3D printers and materials. We also understand just how difficult some of these high-performance materials are. With this PI, we have a material that has given us great results on the printer and testing. We’re really enthusiastic about this material and the possibilities it gives to our customers.”

3D4Makers Filament manufactured with Zymergen Z2 polyimide has comparable

performance to PEEK, but is far easier to 3D print consistently. This material can also lead to higher reliability processes for manufacturing parts. Additionally, parts also do not need to be annealed after printing to perform well. Inherent to polyimide, this material will be applicable for use in harsh environments, and there already has been significant interest from defense, space, energy and racing companies.

This material now available for sampling has demonstrated an (ASTM 1708) tensile strength of MPa 96 and a tensile modulus of 2.41 GPa. The glass transition temperature is 193 C. This polyimide prints at between 390 – 410°C.

Previously polyimide materials have been unstable, difficult to 3D print and parts experienced a lot of warping and cracking. 3D4Makers’ Filament made with Zymergen Z2 polyamide addresses these issues. Its high Z strength is unique and possibly the highest single layer Z strength (currently 80 MPa) available, making it an exciting material for thin wall, high performance parts such as pressure vessels and connectors.

3D4Makers is proud to offer this material to the world; limited sampling opportunities are available. The material is available in its natural colour (amber transparent) and black. 3D4Makers will be printing filament from Zymergen Z2 polyimide at the 2022 Hannover Messe (Hall 3, stand A20, B38).

Find out more at www.3d4makers.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.