As the world works to drive circularity forward, ensuring that products make their way to the recycling facility won’t be enough. It’s time to take recycled materials one step further and systematically create high-quality products that retain, or exceed, their original value. One innovative Dutch interior brand is working hard to prove the potential of large-scale upcycling, demonstrating the direction fully circular design can take us.

Almost 200 billion beverage cartons were produced in 2021 and there are an estimated 5 billion buildings in the world. So what if we were to turn those cartons into high-value architectural material and decrease the need for virgin material used for building and furnishing our daily living and work spaces?

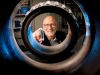

Aectual is a design brand based in Amsterdam and the world’s first platform for 100% circular, 3D-printed interior and architectural products. Working together with Tetra Pak’s Workplace Experience and Real Estate team, Aectual developed a series of uniquely beautiful interior objects and elements made entirely of PolyAl (polymers and aluminium from recycled cartons).

Launched at the Milan Design Fair in June 2022, the Aectual x Tetra Pak concept line is being rolled out incrementally across Tetra Pak’s global facilities.

“Together with Aectual, we developed a playbook with a selection of product designs our workplace teams can choose from to furnish their own environments while implementing workplace projects,” says Sudhir Saseedharan, Director of Workplace Experience & Real Estate at Tetra Pak. “It’s part of our workplace experience strategy to ensure we live up to our promise to protect food, people and the planet in our own work environments every day.”

Products in the playbook include stylish and functional stools, planters, wall panels, room dividers, window screens and more – all 3D printed with PolyAl and 100% circular, because once the designs wear out their welcome, they can be shredded and reprinted into new products.

Going against the grain

The project started when Sudhir’s team asked themselves, “How can we use post-consumer packaging waste in our own furniture and interiors?” Around the same time, Aectual happened to be testing PolyAl with their 3D print designs, working with material they received from a local recycler.

Common wisdom among designers was that PolyAl is not a viable base material – that the aluminium component makes it difficult to work with. But Aectual found the opposite to be true.

“PolyAl is a most impressive material,” says Creative Director and Co-founder of Aectual Hedwig Heinsman. “It’s a bit clay-like and looks like concrete, but it’s really versatile. And the tiny chips of aluminium give it depth and allow the colour to mix well into the material. It has a lovely tactile finish. Based on these behaviours, we are confident we can use PolyAl to produce all the products in our portfolio.”

From waste to wonder: tapping into local recycling streams

Aectual works with range of plastics from virgin plant-based plastic to recycled polypropylene, but they focus on ecosystems where they can tap into valuable recycling streams.

“We work with waste plastics because we see a lot of advantages in the material, but we need large amounts from an identical origin,” says Hedwig. “So, we look for professional industrial partners to help us close the loop: when there is a recycled material in place, we can adapt it to 3D printing.”

95% dedicated to corporate clients, Aectual works with the likes of Nike, Disney, Burberry and more.

“They come for the aesthetics – they love the look of our products – and they stay for the sustainability.”

3D printing leads to an 80% CO2 reduction because products are created using less materials, there’s no stock and production is on demand. Add recycled materials to that mix and Aectual’s products give corporations a real opportunity to reduce their climate impact.

Laying the groundwork for systemic change

“Working with corporate clients makes sense for us as they often have a wide network of facilities to furnish, and they are refreshing their interiors every five years or so. They create a natural place for us to scale our designs,” says Hedwig.

“As our sustainability team always says, for any sustainable innovation to make a tangible impact, it needs to be available at scale,” says Sudhir. “The beauty of Aectual’s platform is that the designs are mass customizable. So, wherever there is reliable recycling infrastructure and willing recycling partners, the PolyAl can be implemented in Aectual’s designs. We see this as the basis for creating real systemic change with PolyAl and that’s what we want to help facilitate.”

And Aectual sees the greater potential with PolyAl.

“Almost 200 billion beverage cartons are produced every year and there are an estimated 5 billion buildings in the world. When you start to think about turning all those cartons into PolyAl, you really see its potential as a new architectural material,” adds Hedwig. “We have already introduced it to several big global architecture firms, and we plan to do everything we can to spread the word about the potential of PolyAl.”

Find out more about Tetra Pak at tetrapak.com.

For more information about Aectual, please visit aectual.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.