6K Additive, a division of 6K, engaging in the production of sustainable advanced materials for additive manufacturing and energy storage, has announced the results of an independent life cycle assessment (LCA) completed by leading sustainability and energy firm, Foresight Management.

This is the first LCA of powder for additive manufacturing ever completed. It sought to compare the quantifiable environmental impacts between traditional metal powder production methods and 6K Additive’s proprietary UniMelt® process. The results show the UniMelt process significantly reduces environmental impact in the key areas of energy usage and global warming, potentially helping 6K Additive customers lower their carbon footprint using metal additive manufacturing.

Frank Roberts, 6K Additive president, said: “This assessment goes a long way in revealing how the UniMelt process exceeds traditional metal powder processing in environmentally important ways, while also pointing to the inefficiencies of atomization that currently plague AM material production. Sustainability is at the core of who we are at 6K Additive and providing our customers with quantifiable numbers related to the environment helps them move closer to zero carbon manufacturing with AM.”

Grand Rapids, MI based Foresight Management conducts life cycle assessments on products for companies to help them understand the impact their processes have on a global environmental scale. Their methodology includes primary and secondary data, as well as using professional GaBi software to provide data detailing environmental impact of sourcing, refining, and processing.

“This is a cradle-to-end user assessment of the UniMelt technology. We studied all known industrial processes from raw material acquisition and processing up through manufacturing and customer distribution,” explained Brad Van Valkenburg, sustainability manager at Foresight. “This assessment focused on nickel and titanium powders, both of which saw significant advantages when made using UniMelt process. The nickel results showed the UniMelt required 91% less energy and reduced carbon emissions by 92% and the titanium results showed the UniMelt required at minimum, 74% less energy and reduced carbon emissions by 78%.”

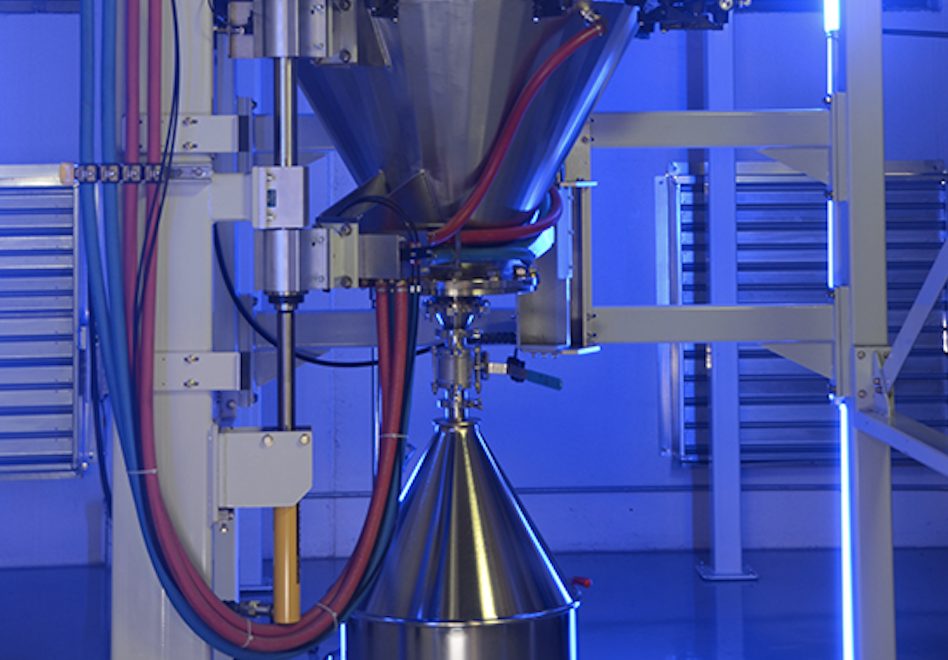

Organizations are starting to look to their suppliers to offer statistics that help them with their sustainability journey. Many companies are now asking for hard facts to back up sustainability claims and this study provides 6K Additive customers with invaluable information that helps them advance their additive manufacturing initiatives. 6K Additive is the world’s first producer of AM powder made from sustainable sources and its UniMelt system is the only microwave production-scale plasma with a highly uniform and precise plasma zone offering zero contamination. UniMelt is capable of high throughput production of advanced materials including nickel 718/625, titanium64 grade 5/23, copper 18450/GRCop, stainless steel 316/17-4, refractories such as tungsten and tantalum.

Companies interested in working with 6K Additive regarding their specific powder requirements are urged to visit 6K Additive’s website 6KAdditive.com.

Headline picture: The First Life Cycle Assessment of Additive Manufacturing Powder Process has been Completed by Foresight Management for 6K Additive (c) 6K

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.