Swedish metal 3D printer manufacturer and developer of Electron Beam Melting (EBM) technology, Arcam, revealed plans to continue to expand its Canada-based powder manufacturing subsidiary AP&C.

May 20, 2016: Having just announced the investment in three new reactors for metal powder production back in March, the company now revealed plans to build yet another one. According to Arcam, the new capacity increase follows on significant growth in 2015 and 2016 and an increased demand for their high quality titanium powders used for additive manufacturing processes. With their current capacity and planned extension, AP&C will reach a capacity of at least 750 tons per year.

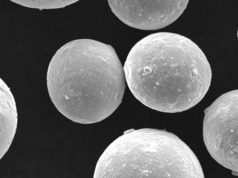

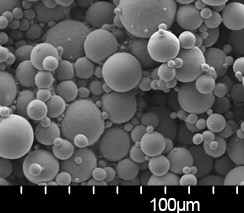

AP&C’s proprietary plasma atomisation technology converts raw material into metal powder, including titanium alloys, nickel-based alloys and others. The powders feature excellent key properties such as flowability, density, chemistry and traceability.

“The need for high end titanium powder is driven by the fast growth and adoption of Additive Manufacturing. Arcam is determined to serve the industry through cost efficient solutions thus converting traditional manufacturing into Additive Manufacturing. A requisite is to offer highest quality powder for production at competitive cost”, said Magnus René, CEO of Arcam.

“The need for high end titanium powder is driven by the fast growth and adoption of Additive Manufacturing. Arcam is determined to serve the industry through cost efficient solutions thus converting traditional manufacturing into Additive Manufacturing. A requisite is to offer highest quality powder for production at competitive cost”, said Magnus René, CEO of Arcam.

Alain Dupont, President of AP&C, stated in a press release: “With this investment we are committing to supply our present and future customers with superior quality materials to meet the high manufacturing standards of the biomedical and aerospace industries. With the powder plant and atomizing technology advancements, AP&C will add significant capacity in 2017 and onwards.”

October 18, 2016: Update – AP&C breaks ground on second plant

Arcam’s powder manufacturing subsidiary AP&C has begun to build its second powder plant in Saint-Eustache, Québec. The ground-braking ceremony for the up to CAD 31 million investment was led by AP&C President Alain Dupont, with ministers and representatives from municipals and industry present.

AP&C will create 106 new jobs within the next three years, in addition to the 85 people currently employed.

“The need for high end titanium powder is driven by the fast growth and adoption of Additive Manufacturing. Arcam is determined to serve the industry through cost efficient solutions thus converting traditional manufacturing into Additive Manufacturing. A requisite is to offer highest quality powder for production at competitive cost”, said Magnus René, CEO of Arcam.

“This investment makes possible to provide our existing and future clients with superior quality powders to meet the high manufacturing standards of the aerospace and orthopaedic industries,” commented Alain Dupont, President of AP&C. “With this new powder production facility and advances in atomization technology, AP&C will significantly increase capacity.”

AP&C benefited from the support, advice and financial assistance of Canada Economic Development, Montréal International, Investissement Québec and the Québec Ministry of Economy, Science and Innovation in moving its expansion project forward.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.