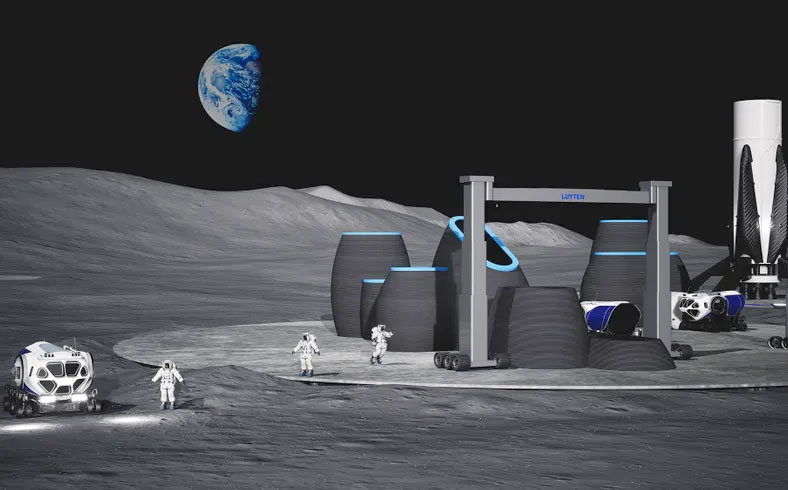

Cutting-edge Australian 3D printing building and construction company, Luyten, has signed an historic Memorandum of Understanding (MOU) with the University of New South Wales (UNSW) to fast-track development and delivery of 3D printing technology to build structures on the moon.

The MOU will see UNSW and Luyten working together to develop, test and implement technology to deliver lunar building solutions.

“We are absolutely delighted and extremely honoured to be partnering with UNSW to make building on the moon possible. UNSW is renowned for its academic leadership and world class research and we couldn’t be more pleased to be working together,” Luyten cofounder and CEO, Ahmed Mahil said.

“Our combined expertise and passion for innovative and exceptional building outcomes involving a range of intertwined disciplines will help the human race to expedite colonisation of the moon and other planets. Our partnership will solidify Australia’s leading role in the world’s fast developing space economy.”

Since launching in 2020, Luyten’s mission has been to make construction easier and more sustainable across a broad range of industries by reducing the time and cost to build, the amount of construction waste generated, and the impact of build activities on the surrounding environment.

Luyten’s cutting-edge 3D printing and additive technologies have become a world-wide success story as companies across the globe scramble to purchase its printers. In response to global demand, Luyten is now expanding the scope of its technology use to moon building.

“When we developed our groundbreaking 3D concrete printers, we thought we would be solving building and construction issues across the world – but with discussions currently taking place with people across the space industry we are now looking at solving building and construction issues on the moon,” Luyten cofounder and CEO, Ahmed Mahil said.

“As a result, we have commissioned Project Meeka. Meeka means moon in some of Australia’s First Nations languages. Our lunar work is advanced and now at a stage where it is fine tuning and testing the types of materials and designs needed for construction purposes on the surface of the moon.

“The 3D printer we have developed to undertake construction on the moon is called Platypus Galacticas.

“This printer is agile and transformable. It can transform from a size of 3m x 4m in height and width to 9m x 12m in height and width, capable of producing a structure of up to 9m x 12m in height and length. The printer can be set up in less than 30 minutes.

“We have designed the printer for compactness using light weight composites for its structure and robotic transforming technology, making it ideal for space transportation purposes.”

According to Associate Professor Matthias Hank Haeusler, the Discipline Director of the Bachelor of Computational Design (CoDe) at the Australian School of Architecture + Design (Built Environment), UNSW, the MOU will ensure the country’s greatest minds are involved in capacity building for lunar construction.

“With Computational Design one has a method to design protective shells for habitats on the moon – with a foremost consideration on requirements for human habitat in mind. Computational Design allows to feed in scientific knowledge on how to protect humans from solar and cosmic radiation into a script that generates a shelter with the required 80 plus centimetres of solid material while optimising the structure towards the print process,” Associate Professor Haeusler said.

Constructing a lunar settlement is a highly elaborate mission and will require significant technology.

“First, rovers with ground penetrating radar will assess the location’s structural capacity to build. Meanwhile other rovers with ultrasonic props and excavation capabilities will start harvesting lunar regolith. In order to source building materials from the regolith and then characterise its mechanical properties, the excavation rover will deposit collated lunar dust at a regolith sorting reservoir where it will be processed to a finer size. The transforming robots will then initially construct shell structures at the building site,” Mahil explained.

Associate Professor states: “This information can become part of the Computational Design script and the design will respond to the specific material properties identified on site. Thus, each habitat is customised for the material on site such as the radiation and the printing process, and fed directly to the Platypus Galacticas 3D printer.”

“After sourcing 3D printable material, the Platypus Galacticas 3D printer will start printing on the compacted lunar surface. The extrudable materials will then be passed through the printing nozzle and form the layers of the structures,” Mahil continued.

“Moon regolith will be the primary building material of the printed structures due to its abundance. Based on the material properties of the specific type of regolith, concentrated microwaves will be used to sinter the regolith into a printable form.”

Mahil points out that space technology benefits the human race every single day.

“A lot of the daily conveniences that Australians have come to expect, are actually underpinned by space-based technologies. It is easy to forget that things such as internet access, weather forecasting, GPS, online banking and emergency responses to natural disasters all heavily rely on the innovations floating in space above the earth’s surface,” Mahil added.

Haeusler agrees, “the knowledge we generate for building on the moon can be translated directly into building housing for extreme climates such as heat or for addressing housing issues in remote indigenous communities – both topics we investigate in parallel.”

“We are proud and excited to be recognised for our technology’s space capabilities and compliances. Our team at Luyten is working hard to remove barriers to construction in hazardous conditions, such as on other planets, by producing reliable technology, and our MOU with UNSW will only bolster this work,” Mahil emphasised.

“With Australia investing funds and focus into a space strategy we believe we are perfectly positioned to support Australia’s aims in advancing involvement in securing the future of space. The Australian Civil Space Strategy 2019 – 2028 outlines a clear opportunity for Australian innovation, technology and industry thought leaders such as Luyten.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.