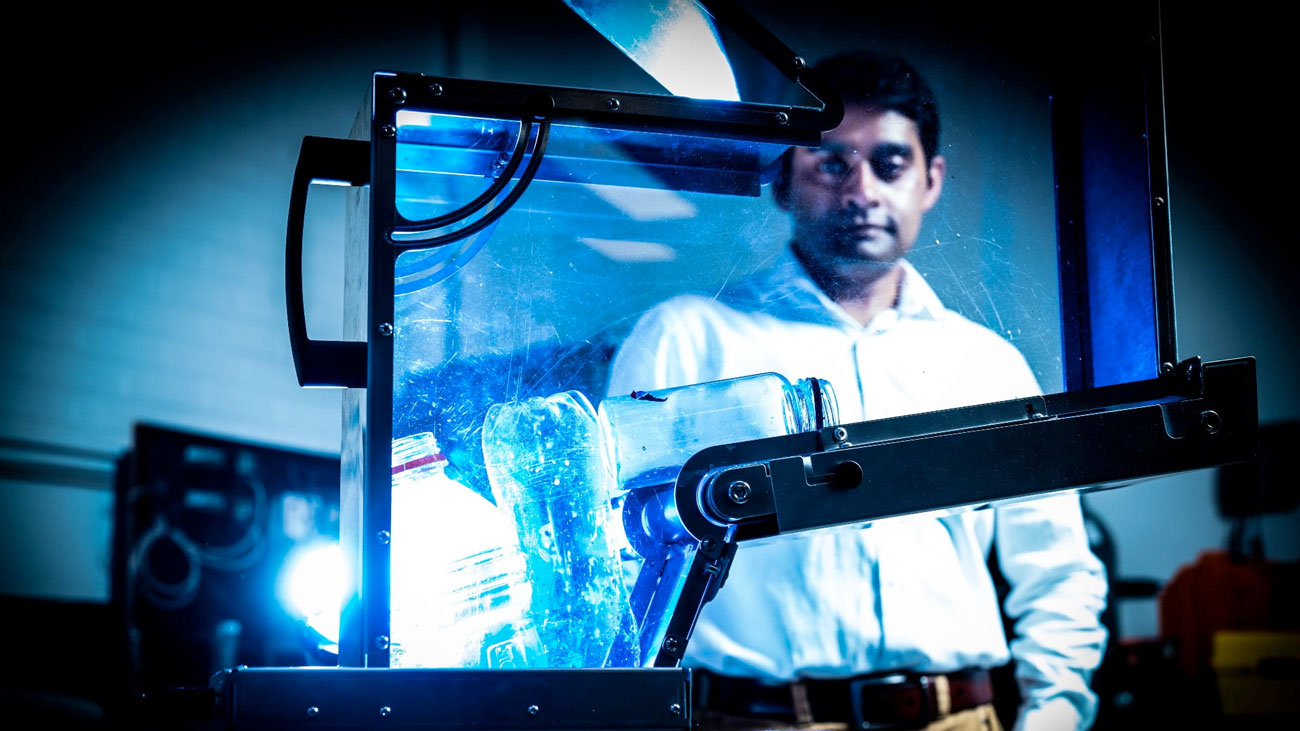

In a project titled “Designing for Circular Economics: Creating Impact from Local Plastic Waste Using Off-Grid Containerized 3D Printers and Practice Based Learning,” the University of Wollongong Australia (UOW) aims to explore more sustainable manufacturing with 3D printing. With support from the National Science Foundation in the United States and CSIRO in Australia, Dr. Ahmed, leader of the UOW project, is working on a team led by Texas-based re:3D. The interdisciplinary team also includes researchers from Austin Habitat for Humanity, the University of Texas at Austin and Western Sydney University.

As part of the project, the UOW team will focus on the net zero aspect in the design of a scalable and accessible, net-zero-footprint 3D printing-based manufacturing system that is comfortable to work in, can be moved easily between construction sites and enables lay users to design and manufacture goods from plastic waste onsite. The result? Furnished homes that are sustainable, functional, and aesthetically pleasing, with a significant socio-economic impact.

The design, which will be informed by the requirements of Habitat for Humanity, will be able to be deployed around the world, and completely open source.

Dr Ahmed said the global project was truly multidisciplinary and collaborative.

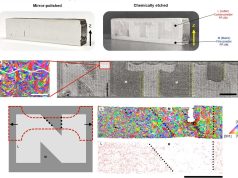

“It leverages re:3D’s expertise in 3D printing directly from plastic waste, Habitat for Humanity’s desire to scale demand for customised 3D-printed home goods made from plastic trash, The University of Texas at Austin’s expertise in engineering design, sustainability, and Life Cycle Analysis, UOW’s expertise in the built environment, and Western Sydney University’s experience in the materials science of 3D printing with recyclables.”

Dr Ahmed said he was thrilled to be working on such forward-thinking and innovative research.

“Imagine a world that supports the sustainable manufacturing of furnished homes using local plastic waste, while not only diverting garbage from landfills but also creating jobs and training under-represented talent. What if this opportunity could be scaled globally in both rural and urban areas in a modular package?”, Dr Ahmed said. “I am very excited for the opportunity to work on such a visionary project, and even more so as it is under the umbrella of National Science Foundation’s Convergence accelerator program, which aims to accelerate convergence research into application and commercialisation.”

Professor David Currow, UOW’s Deputy Vice-Chancellor (Research and Sustainable Futures), congratulated Dr Ahmed on the grant funding and said he was looking forward to seeing how the research developed.

“As we all know, the problem of how to deal with the immense amount of plastic waste on this planet is both urgent and overwhelming. This novel research could have a significant role to play in helping the environment while creating a significant and positive social impact. Congratulations to Dr Ahmed and the UOW team on their success in this prestigious round of international funding.”

Find out more about the UOW at uow.edu.au.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.