A team at RMIT University in Melbourne has created a new class of titanium alloys that are strong and non-brittle in tension by integrating alloying and 3D printing techniques.

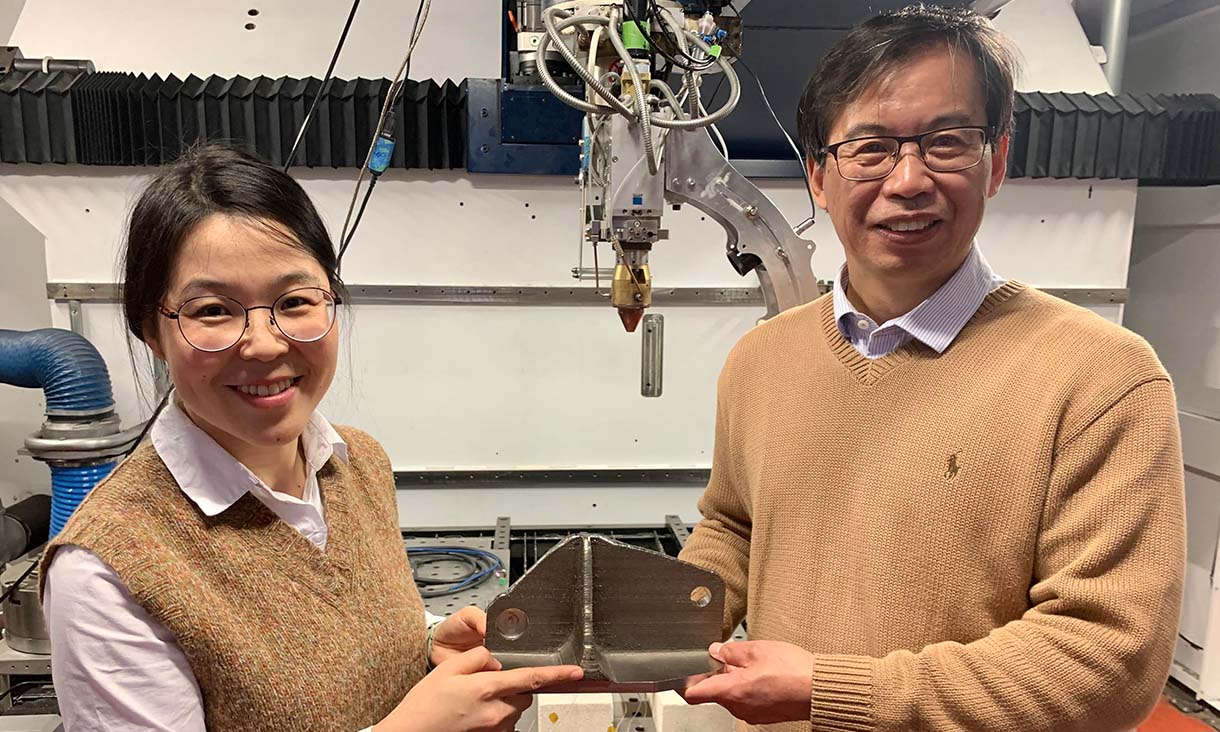

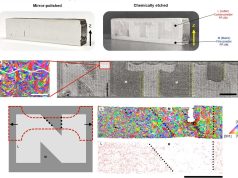

The innovation was driven by RMIT University and the University of Sydney in collaboration with Hong Kong Polytechnic University and Melbourne-based Hexagon Manufacturing Intelligence. The team’s titanium alloys are composed of alpha-titanium and beta-titanium phases, reinforced with oxygen and iron. These favorable and abundant elements have previously hindered the development of strong and ductile alpha-beta titanium-oxygen-iron alloys.

“Reusing waste and low-quality materials has the potential to add economic value and reduce the high carbon footprint of the titanium industry,” said Qian from RMIT’s Centre for Additive Manufacturing in the School of Engineering.

The researchers used the Laser Directed Energy Deposition (L-DED) 3D printing process to print their alloys from metal powder.

“A key enabler for us was the combination of our alloy design concepts with 3D-printing process design, which has identified a range of alloys that are strong, ductile and easy to print,” Qian said.

The novel alloys rival commercial alloys and offer a broad and tunable range of mechanical properties. Their use allows for significant reductions in emissions and tremendous potential for innovative material designs. The researchers emphasize the potential of their findings for applications in aerospace, biomedical, chemical engineering, space, and energy.

Lead author Dr Tingting Song, RMIT Vice-Chancellor’s Research Fellow, said the team is “at the start of a major journey, from the proof of our new concepts here, towards industrial applications.

There are grounds to be excited – 3D printing offers a fundamentally different way of making novel alloys and has distinct advantages over traditional approaches. There’s a potential opportunity for industry to reuse waste sponge titanium-oxygen-iron alloy, ‘out-of-spec’ recycled high-oxygen titanium powders or titanium powders made from high-oxygen scrap titanium using our approach.”

Find out more about the RMIT University at rmit.edu.au.

For more information about University of Sydney, please visit sydney.edu.au.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.