Considerable Cost Calculation Benefits for Tool Manufacturing and a Massive Cost Reduction in Automation and Measurement Technology:

BorgiForm Is Convinced by the Performance of German RepRap 3D Printers

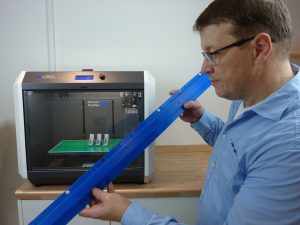

BorgiForm, a young, innovative family business headquartered in the heart of eastern Westphalia (Germany), focuses its business literally “shaping” ideas. Dirk Kriegel, Managing Director, introduced 3D printing technology a while ago. Additive manufacturing simplifies the company’s work and is used in the development of die-cutting and bending tools as well as in automated manufacturing. The main benefits include considerable cost reduction in the areas of automation and measurement technology as well as simplified cost calculation in tool manufacturing.

“Shaping” means that the customer’s ideas are converted into 3D data by a CAD tool, so they can subsequently be produced by a 3D printer. Production is executed by the German RepRap 3D printers: X350Pro and X400.

This new manufacturing process allows for the production of cost-effective plastic parts for use in product development, prototyping, model and mold construction, as well as architecture and design.

Kriegel is a master precision machinist working in the area of die-cutting and bending tool production for the automotive industry. One of his tasks is the technical evaluation of newly requested die-cutting and bending parts. 3D printing a copy of the intended product for technical and business calculations has turned out to be very helpful for the company. Since a supplier of these 3D printed parts was needed who was familiar with the industry, Kriegel decided to start his own small manufacturing company. More and more companies became aware of this profitable service, and today, BorgiForm’s customers include gauge manufacturers and many others in the plastics and furniture industries.

Kriegel has been excited about 3D printing technology from day 1. “By recognizing and correctly evaluating issues before production, and using the parts in the area of measuring, total project costs can easily be reduced by around 20%. Compared to the savings, the cost of 3D printing the part can be considered very minor,” explained Kriegel. He elaborates on proactively identifying issues. “CAD data on a computer doesn’t provide an accurate feel for the size and scope of the part to be produced. For all practical purposes, it is much easier to identify and evaluate potential issues with the final product on a full-scale 3D printed part, which also saves cost. In addition, 3D printed parts can be used as preset models in measurement engineering. Optimizing measurement routines using a 3D printed part allows for streamlining of measurement programs before the actual part is available. Again, this leads to a potential reduction of personnel and equipment cost.”

So far, PLA and ABS have been the types of material predominantly used, but many other materials are also available. These include PS, PVA, TPU 93, Carbon 20, Laywood, Laybrick, PP, Bendlay, Soft PLA, and Smart ABS. In general, the choice is based on the client’s requirements. In order to obtain flawless printing results with these materials (also called filaments in 3D printing terminology), following the manufacturer’s specifications is crucial.

BorgiForm ended up choosing German RepRap’s system, since this German manufacturer allows direct contact. “We felt like we were getting excellent guidance. The short distance to their facility is very helpful, especially with technical issues. Another reason for choosing German RepRap’s machines was their robust construction capacity: the printers were developed using industrial specifications, and that is important. Also a plus is being able to fix technical issues ourselves with some guidance from the manufacturer. This ultimately saves time,” said Kriegel.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.