Just a week ago Boston Dynamics released a video of their humanoid robot, Atlas, which got more than 12 million views in just six days.

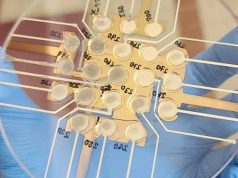

To make this incredible robot possible the team from Boston Dynamics utilised the advantages of additive manufacturing. As Marc Raibert, the founder of Boston Dynamics, told the audience at the Fab 11 in mid 2015, Boston Dynamics is visioning a future where most parts of their robots take advantage of additive manufacturing. He also showed an example (image below) for an additive manufactured vision of a feet of one of their robots.

With the use of additive manufacturing all the hoses, which are needed for the hydraulics, can be integrated into the leg itself. Also the structure can take advantage of 3D printed lightweight design, like a honey comb infill of the leg.

As IEEE Spectrum found out the techniques, described above, are used to make the new version of the Atlas happen:

“The engineering team did a huge amount of work to make ATLAS lighter and more compact,” Marc Raibert, founder and president of Boston Dynamics, told IEEE Spectrum. “One thing we did was use 3D printing to create the legs, so the actuators and hydraulic lines are embedded in the structure, rather than made out of separate components. We also developed custom servo-valves that are significantly smaller and lighter (and work better) than the aerospace versions we had been using.”

Watch Marc Raibert´s presentation at Fab 11:

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.