Industrial 3D-printing has long been used to produce only prototypes. In the meantime, also market-ready products are produced with the technology. One reason for this are innovations in the field of post-processing, which enable high-quality surface finishes and unlimited color options. Many brands and manufacturers of consumer goods already benefit from the advantages of this flexible and sustainable technology. The ability to individualize applications for customers, to produce On-Demand and to react quickly to trends opens up completely new possibilities.

For the Coffee & Cases series, DyeMansion visits customers on site to learn more about their applications. In this episode Marie Boltenstern, CEO & Head of Design at Boltenstern and Robert Razavi, CEO & co-founder of FORMRISE talk about the creation of the Fabnora collection.

In cooperation with DyeMansion, the global leader in Additive Manufacturing finishing systems and production partner FORMRISE, the young designer Marie Boltenstern succeeded in launching her own collection of 3D-printed earrings. Her designer pieces are available in three different sizes and in over 15 different colors. In her shop in Vienna and online they are sold in combination with elements made of sterling silver for 140€.

Boltenstern is inspired by geometric shapes and patterns coming from nature, for example fish scales. “What looks organic follows fixed mathematical rules and patterns,” says Marie Boltenstern. When it comes to the materials used, Marie focuses on diversity. When she heard about the first precious metal printer from Cooksongold and EOS back in 2014, she was immediately thrilled and saw great potential in combining her passion for modern technology with jewelry design. This is how her first 3D-printed gold collections were created.

She now uses polyamide for her Fabnora collection, which she originally used to test new designs. She quickly noticed that the material’s properties also made it suitable for series production. In order to meet her quality standards and color preferences, she started working with DyeMansion and FORMRISE. The German 3D-printing service provider has a lot of experience in the consumer goods sector and knows what is important for designer pieces. FORMRISE has been advising Boltenstern since the beginning of the cooperation not only on the optimization of the CAD models, but also on the correct positioning of the parts and the selection of the appropriate 3D-printing technology.

“With DyeMansion’s technology and our know-how, we can guarantee Boltenstern a stable, reproducible and above all holistic process”, says Robert Razavi, CEO & co-founder at FORMRISE.

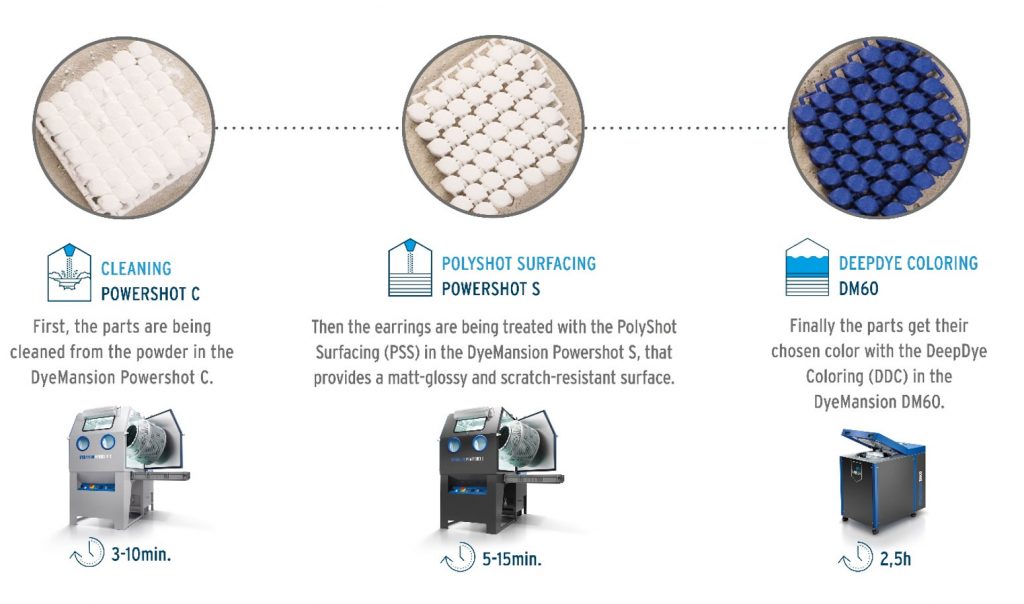

For reproducible finish and color, FORMRISE uses DyeMansion’s print-to-product workflow. DyeMansion’s solutions for automated cleaning, surface treatment and coloring can be used flexibly for all common 3D-printing technologies in the field of plastics, regardless of the part geometry.

From white raw part to end-use product

The polyamide earrings are produced at FORMRISE on a Formiga P 110 from EOS. Fine, movable structures that could not be produced by hand are not a problem anymore, thanks to the precision of the Formiga P 110. The raw parts are then automatically cleaned in the DyeMansion Powershot C. In the DyeMansion Powershot S, the parts are given an improved feel and a matt-glossy look with PolyShot Surfacing. The mechanical process takes 10 minutes and, compared to grinding, does not remove any material. The pendants are then colored with the DeepDye Coloring (DDC) process in the DyeMansion DM60. “From the very beginning, it was important to be able to offer the customer variety in the form of different colors – while maintaining consistent quality,” says Marie Boltenstern. Dyeing 3D-printed parts has long been a manual, uncontrollable process. DyeMansion’s process relieves users of this process and provides them worldwide with color recipes down to the microgram. This enables an industrial process that could not be easier for the user and can be reproduced any time. The power lies in the color cartridges, which are manufactured depending on base material, finish and desired color. Based on the volume of the parts, DyeMansion deliver cartridges in four different sizes. These are equipped with an RFID chip that transfers all process parameters QM ready to the DM60.

Unlimited color options: From standardized database to seasonal Pantone trend colors

“Our customers want to react quickly to the requirements of the market with their choice of colors. That’s why we offer both, a standardized color database and customized colors,” says Constanza Oszwald, R&D Engineer at DyeMansion.

Marie Boltenstern was also concerned with maximum freedom in the choice of colors when developing her collection, so that she could react to current trends at any time. DeepDye Coloring sets no limits to her wishes. In addition to a standardized color database of over 170 RAL colors, Boltenstern uses the Color Matching service from DyeMansion.

This gives the designer the opportunity to expand her range at any time with the latest trend colors and seasonal special colors. A good example is the official Pantone color of the year 2020, Classic Blue. In the next few days, the label will launch a limited edition in the elegant, timeless color. The earrings will be available both online and in the Vienna showroom.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.