Seattle-based entrepreneur Michael Toutonghi has developed a conductive 3D printing filament and is currently seeking for $ 100.000 on Kickstarter to fund production.

November 10, 2014: The so called Functionaize F-Eletric filament is supposed to be one thousand times more conductive than any other 3D printing filament. The idea for this was born during working on his son’s science fair project. Mike wanted to integrate electromechanical capabilities inside of 3D printed objects. He then set up a laboratory in his home to make graphene and experiment with nano-composite materials. After years of research a formulation and production process has been developed.

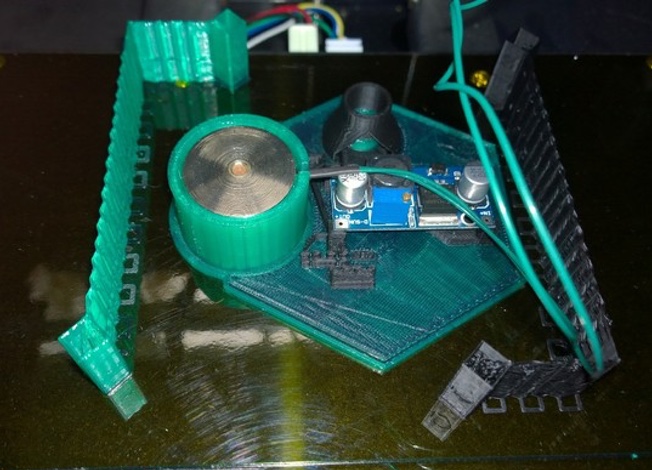

Among the first 3D printed functional devices Mike created is a 3D printed keychain flashlight, an electro-magnetic lockbox and an electro-magnetic levitator. These will also be available during the Kickstarter campaign until 10th December.

April 7, 2015: Update – F-Electric 3D printing filament released to market

After several month of further development, Functionalize has released its conductive filament to the market, selling it through their webshop. According to the startup, F-Electric has beaten its promised electrical specification by 25%. The final production material has a resistance of 0.75 ohm/cm and features a mechanical strength that is better than its previous beta material as well as virgin PLA.

Mike Toutonghi, CEO and Founder of Functionalize, Inc. said at the 2nd Additive Disruption Summit in Santa Clara: “We’re super excited that were we able to get our process into production and ship in March. More than that, we’re pleased to deliver a product to customers that exceeds both our electrical and mechanical property goals.”

“Imagine the possibility of today’s 3D printed prosthetics being able to sense pressure through conductive pads in their fingertips, printable robots that people could share and improve, or active wearables as creative as their maker,” said Toutonghi. “We’re excited to be at the beginning of this trend. Shipping F-Electric is a historic milestone for Functionalize for our company and our customers. We’ve provided a new tool, and I can’t wait to see what creative people can do with it.”

In one of their current blog entries, Functionalize gave some tips and tricks to get the best possible F-Electric 3D printing experience. The ideal nozzle temperature should be set between 220°C and 230°C and the bed temperature anywhere between room temperature and 65°C. F-Electric does bond quite well to PLA and if possible, the print head travel direction should be along the line you want electricity to flow.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.