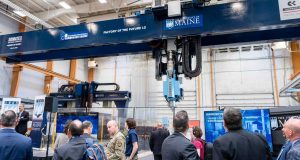

Conflux Technology cooperates with Rocket Factory Augsburg in the development of heat exchangers for aerospace applications as part of the Australian Space Agency’s Moon to Mars initiative.

The A$1 million grant will be used to design and manufacture this 3D-printed heat exchanger.

“Conflux is partnering with RFA to embed next generation heat exchange technology into a rocket engine. At Conflux we are establishing ourselves as leaders in the development and commercialization of 3D printed thermal solutions and relevant materials for extreme applications. With support from the Australian Space Agency’s Moon to Mars Grant Supply Chain Capability Improvement grant, we are now applying it to the rapidly expanding space industry”, says Dan Woodford, Chief Commercial Officer, Conflux Technology.

The Supply Chain Capability Improvement Grant Program is part of the Australian Space Agency’s Moon to Mars Initiative. The initiative supports Australian organizations with projects that could contribute to NASA’s inspiring plan to fly to the Moon and on to Mars. This initiative is also an important element of the agency’s goal to transform and grow the Australian space industry. Conflux is proud to be one of the innovative Australian companies to receive funding under this initiative.

Conflux Technology’s additively manufactured microstructures and internal geometries enable precise control of the surface to fluid ratio to maximize heat transfer and optimize turbulence and pressure drop.

Find out more about Conflux Technology at confluxtechnology.com.

For more information about Rocket Factory, please visit rfa.space.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.