Since its inception, 3D printing has seen a wide area of applications, but a general approach to printing onto unknown objects had not been tackled before the development of InSPIREd. Nowadays 3D scanning technology can be used for reverse engineering. Multiple axis machines enable the creation of object layers at different deposition angles, and printing on uneven surfaces is achieved by conformal printing.

A recent research project at the University of Portsmouth, UK, has combined 3D scanning, multiple axis 3D printing, and conformal printing to create an affordable 3D printing system, which can deposit material onto a priori unknown uneven objects. InSPIREd stands for Integrated Seven-axis Printer/scanner Reactive SurfacE deposition.

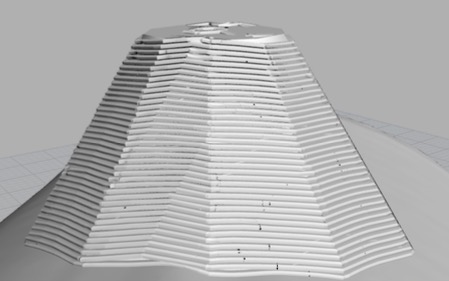

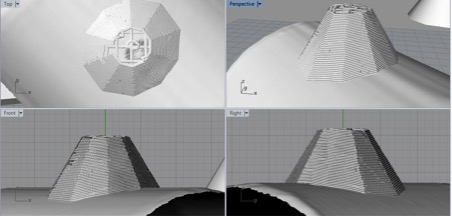

A prototype system was developed, which can print multi-layered objects on top of a previously unknown object, as illustrated in Figure 1.

The application areas for such a method could include repairing structures, product customization, printing security features on existing objects, adding functionality by, for example, printing antennas on items, and modifying prosthetics to fit individual patients.

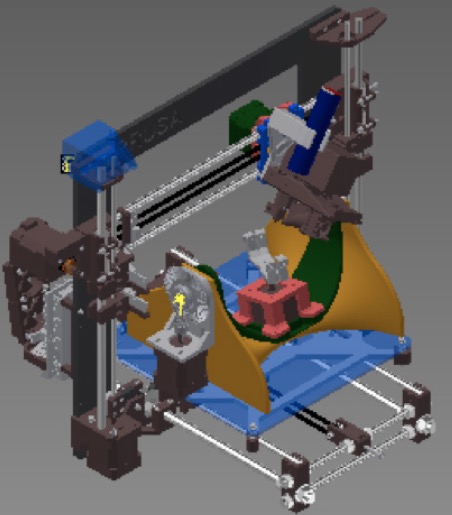

Here are some of the features of the InSPIREd printer (Figure 2):

- Scanning objects with a line laser sweep using a camera & HP 3D Scan Software Professional (formerly known as David4 Pro), exporting point cloud data

- Aligning a new object with the scanned object and creating a toolpath with Rhino/Grasshopper

- Printing the new object using a modified RepRap Prusa i3 3D printer to incorporate 7 DOF with Duet/Duex 4

You can read the full paper here.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.