Dan Woodford is Chief Product Officer at Conflux Technology, based in Melbourne, Australia. In a time of rapid growth at the company, we sought out his insights on topics ranging from innovation and product strategy implementation in 3D printing (additive manufacturing) to the future of heat exchange and AM.

What does innovation in the world of 3D printed heat exchangers look like?

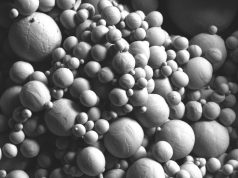

Dan Woodford: “Innovation isn’t just about ‘inventing’; it’s also about deriving value from new ideas. For example, a big challenge for additive manufacturing (AM) heat exchangers is delivering performance. Beautiful and organic parts commonly shown as AM heat exchanger may mix fluids well, but if they grossly disrupt flow and cause massive pressure drops it’s an undesirable outcome.

It’s essential to mesh design for additive manufacturing (DfAM) into every point in the process, being extremely clear on the thermal and performance outcomes and adapting the manufacturing process iteratively to accommodate the design and outcome.

Innovation when designing for AM means knowing exactly what the machines are capable of, and then producing consistent results at the boundary of these capabilities.

As well as developing thin, gastight walls and complex morphology, Conflux has been developing heat exchangers with different surfaces to suit each fluid that flows through the unit. We vary structures within the channels to accommodate the changing properties of different fluids as they heat and cool. We also design for powder removal and have honed the process and design to great effect.”

What does a product strategy for a 3D applications company look like?

“Conflux Technology began life with several insights around using additive manufacturing to do things that no one was having success with at the time – developing usable 3D printed heat exchangers.

We saw that by bringing together innovations in engineering design and additive manufacturing technology, there was an opportunity to create lightweight thermal applications with game-changing performance. Working with our lighthouse customers in aviation, motorsport and energy, we learnt a lot, and leveraged that know how to develop a number of heat exchanger core designs that we were able to apply to more and more thermal problems. Most importantly, we learnt how to print thin-walled, complex structures that hold pressure – the peak challenge for AM heat exchangers.

The sorts of innovations that are possible with these integrated skills are really exciting.

Now, we’re entering a new phase of organisational development; we’re challenging ourselves to scale our know-how into applications that can proactively address market needs with all the benefits of AM.”

What are you currently focused on?

“We’ve got five configurable products slated for release this financial year (2022-2023), so my current focus is to ensure we’re speaking to the customers who’ll get the biggest benefits, and then deliver that value to them.

The design freedoms afforded by 3D printing are vast so, from a product perspective, we want to perfect a balance between developing specific applications and broader categories that can inspire new and innovative products.”

Listening to you, it sounds like Conflux has a strategy to pursue configured products. How does a customer make the decision to go bespoke or configured?

“We undertake a thorough discovery process to really understand a customer’s heat exchange problem. Then, we guide them through the entire selection process.

Our configurable products are built upon the same technologies we’d apply to a bespoke product. We have a virtual library of Conflux core heat exchangers, and we’ve got tools whereby we plug in the boundary conditions, and the requirements from the customer, and we can calculate exactly what size of heat exchanger is required.

It saves so much time because we’ve already put the work into the design, and we can arrive at the first sizing to use within hours. There’s still engineering work to be done, but every single hour that’s saved in design is one that the customer doesn’t need to pay for.”

You’ve got five products that you’re going to launch by the end of the year. Are you able to share what any of these applications are with us?

“One product we’re working on is a cartridge heat exchanger. The concept behind it is to embed an additively manufactured core into a larger system, like a traditionally manufactured casing or an integral part of another component like a gearbox housing.

In use cases where access is a key issue, it means you can access the bit of the heat exchange unit that gets dirty, pull it out and replace it. A continuous process with several units in parallel can avoid any shutdown for maintenance and save a lot in costs. That’s a product category that we’re seeing a lot of applications for.

We’re also going to be launching multi-domain — or multi-fluid — heat exchange technology, where several different fluids transfer heat within one unit.

Our AS9100D certification is a step towards unlocking aerospace markets, and Conflux will leverage our recent AU$1 million grant from the Australian Government to embed our technology into a rocket gas duct to pursue more space applications.”

There’s been talk around the challenges of mass scale production in AM. How is the industry addressing this, and what is Conflux doing in this space?

“It’s a really interesting question – the challenges to ramp up into being a mass production technology is one for our whole industry. They’re complex, but I think that there’s a couple of critical ones that need to be addressed.

One problem is simply the cost of production. The price of AM machines is a comparatively large cost associated with printing parts, as well as post-processing costs. So, lowering machine costs or increasing speeds is vital.

There’s also the selection of applications. We are limited by build volume as well as the long time to print large parts. We’re trying to be more cost-effective and competitive by printing smaller parts focusing on high value heat exchange. For example the cartridge will take less time to print than 3D printing a housing.

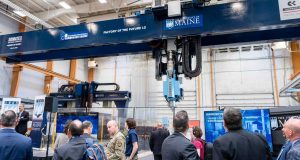

But large amounts of heat transfer ultimately need larger parts, meaning modular designs or larger machines.

Another aspect to scaling is having a robust industry standard certification, verification and testing processes. At the moment, industry standards for AM certification still maturing. We want to contribute to this. As well as commencing AS9100D certification, we’ve brought on Andrew Milner, a registered aerospace auditor and thought leader, to drive our quality management.”

What do you see happening in the industry over the next five years?

“A lot of the promises of AM will start being delivered. The significant increases in production capability will start shining through. There are a lot of companies out there doing service bureau work and printing around the world, so we’ll see the trend towards distributed manufacturing accelerate.

Intellectual property protection capabilities are commercialising. Companies like ours can safely print our parts anywhere in the world, and an increased ability to print to scale will be a paradigm shift. Materials investigation and research will no doubt yield interesting things that we can build – new materials, new coatings, new applications, new surprises that will help us as well.

Additive manufacturing has a bright future.”

Find out more about Conflux Technology at confluxtechnology.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.