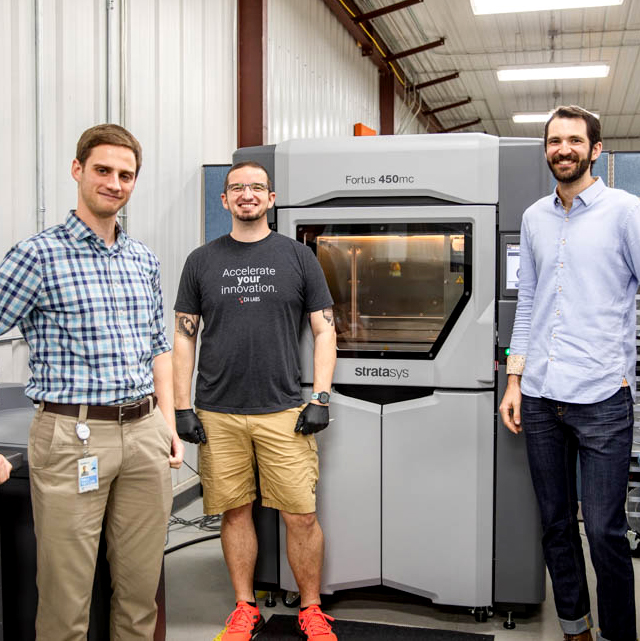

Stratasys recently named DI Labs a global launch partner for their new #OpenAM Software & Validated Materials beta program. Through the beta, DI Labs will be first in the world and the only US location to gain access to the inner workings of the Stratasys Fortus 450MC, an FDM machine that is notorious for having a closed, locked-down platform that limits access to materials and printing controls.

The Stratasys OpenAM beta will give DI Labs unprecedented freedom to modify the process settings and other adjustments necessary to successfully run new, highly engineered materials such as PAEK, PEKK and HIPS on one of the industry’s most consistent, powerful, FDM machines.

Carl Douglass, DI Labs CEO, explains, “We’re excited to ‘Free the Fortus’ of constraints that have been holding this powerful machine back from offering a whole new generation of additive solutions. The level of freedom and access DI Labs will have through this beta has never been granted to an outside entity and we’re excited to be leading the charge!”

Last week, DI Labs started their mission to “Free the Fortus” located in their FDM innovation hub and began testing some of the industry’s most sought-after engineered materials for high-performance applications like medical device, aerospace and automotive. Validated materials like AM200 PAEK from Victrex and PEKK-SC from Kimya are an ideal fit for many projects in these applications but running them has not been possible due to the closed Fortus platform.

Brian Douglass, DI Labs COO, explains, “We’ve got lots of experience running highly engineered materials on open-source machines, but it requires an intense amount of customization. Gaining access to the G-code and print controls so we can successfully run these new materials on a machine as powerful and consistent as the Fortus 450MC will help us change what’s possible for high-value applications where things like complexity, mechanical strength and chemical resistance are absolutely critical.”

DI Labs began the beta program on September 12 and it’s expected to run for 90 days. Stratasys Industrial Business Commercial Leader, Tom Leach, shares, “DI Labs is an excellent partner for the Stratasys OpenAM Software & Validated Materials beta program because of their experience, knowledge, solutions-driven approach to additive manufacturing, and the industries they support.”

Carl Douglass adds: “DI Labs is wholly committed to providing solutions, which has inspired us to invest early and often in the very latest additive advancements. This OpenAM beta is a perfect fit for our unique, problem-solving culture and deep expertise with materials and the inner workings of the additive technologies we operate.”

DI Labs is currently accepting special projects for this beta. For those interested, please click here.

DI Labs is located in Minnesota and owned by brothers Carl, Brian, and Sean Douglass. They have created a unique company culture founded on the principle “there’s always a solution,” which has allowed them to defy the odds and build one of the fastest-growing technology companies in the Midwest.

Follow their Youtube playlist to stay updated.

Find out more about DI Labs at dilabs.cc.

For more information about Stratasys, please visit stratasys.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.