Dimensionics Density has introduced automated density determination technology for additive manufacturing (AM), with a particular focus on validation of AM parts.

Philipp Pruesse, Head of Sales at Dimensionics Density, says, “Our technology directly addresses the need for automation in AM part validation and quality control, and we have launched a suite of tools focused on AM part density determination. For AM to continue to break the manufacturing paradigm, the entire AM process chain must be automated. For this reason, our density determination solutions are fully automated and, most importantly, designed for use in production, not just in the lab.

As we all know, AM promotes design freedom because it is independent of part complexity. As geometric complexity increases, density determination of AM parts becomes increasingly difficult with standard density determination technologies. Dimensionics Density solutions can easily determine the density of free-form and highly complex AM parts and measure density to 0.001 g/cm3 in a repeatable manner.”

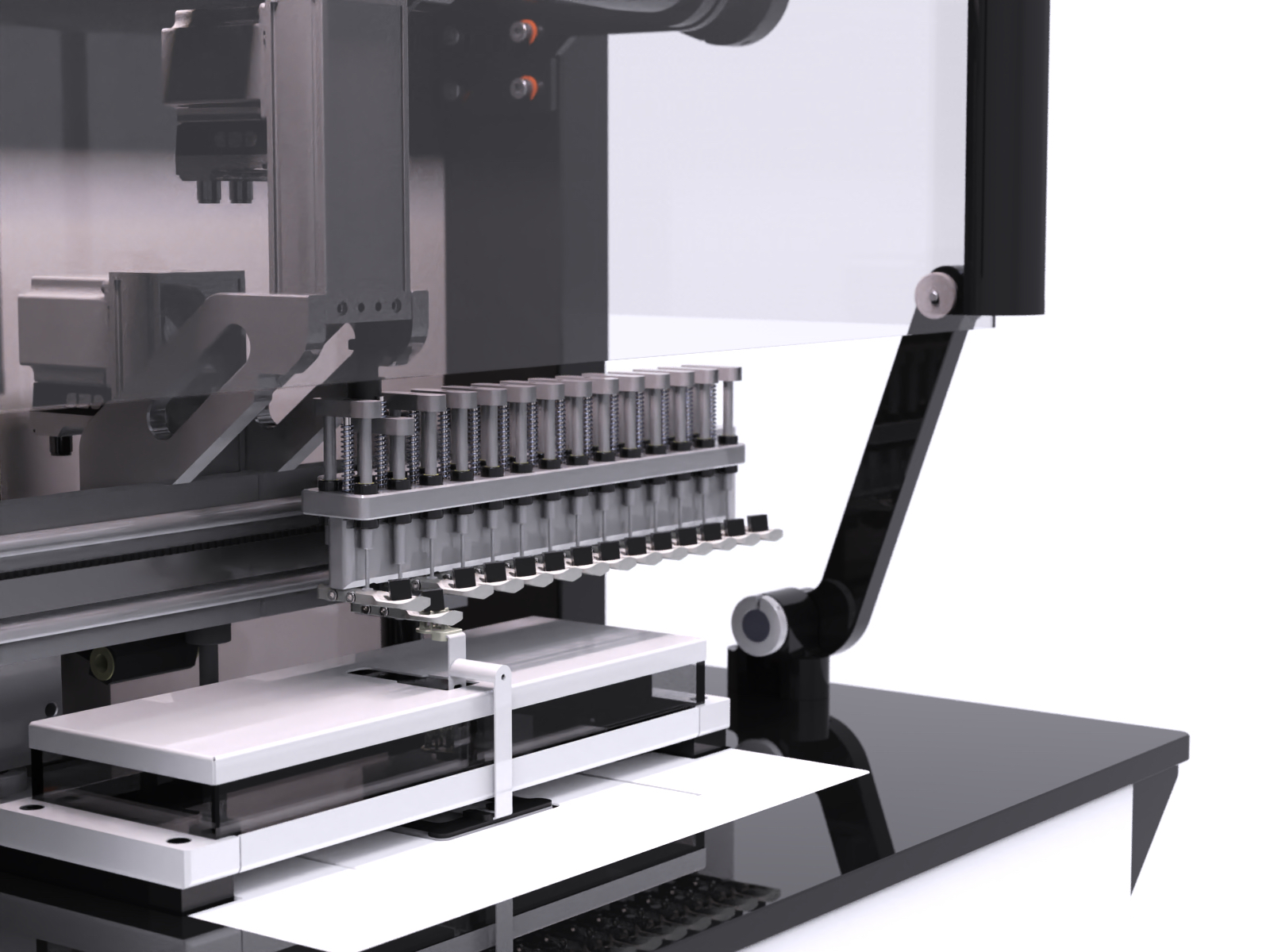

Density determination is especially important because porosity in AM parts can affect their mechanical strength, stability and durability. Dimensionics Density combines the Archimedean principle with automation technology and precision scales to achieve high accuracy. The system is fully automated, and measurements are monitored by integrated measurement and control systems to account for environmental factors.

Dimensionics Density technology is non-destructive and enables fast, accurate and cost-effective verification of AM parts that do or do not meet density requirements.

Pruesse continues, “To counteract this problem and to ensure the repeatability of the measurements, Dimensionics Density offers a universal carrier which can transport most parts, and which can be easily adapted if necessary for more complex geometries. The determined density is compared with the desired specifications, and so qualitatively more accurate assumptions can be made about the density of complex components. With a cycle time of less than 2 minutes per component and the possibility of inspecting up to 18 components simultaneously in one inspection process as standard, the Dimensionics Density solution supports the optimisation and efficiency of manufacturing processes.”

Dimensionics Density’s density determination technology is non-destructive and, therefore can be used to verify parts that conform to density requirements and those that don’t in a speedy, precise, and cost-effective manner.

Find out more about Dimensionics Density at dimensionics.de.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.