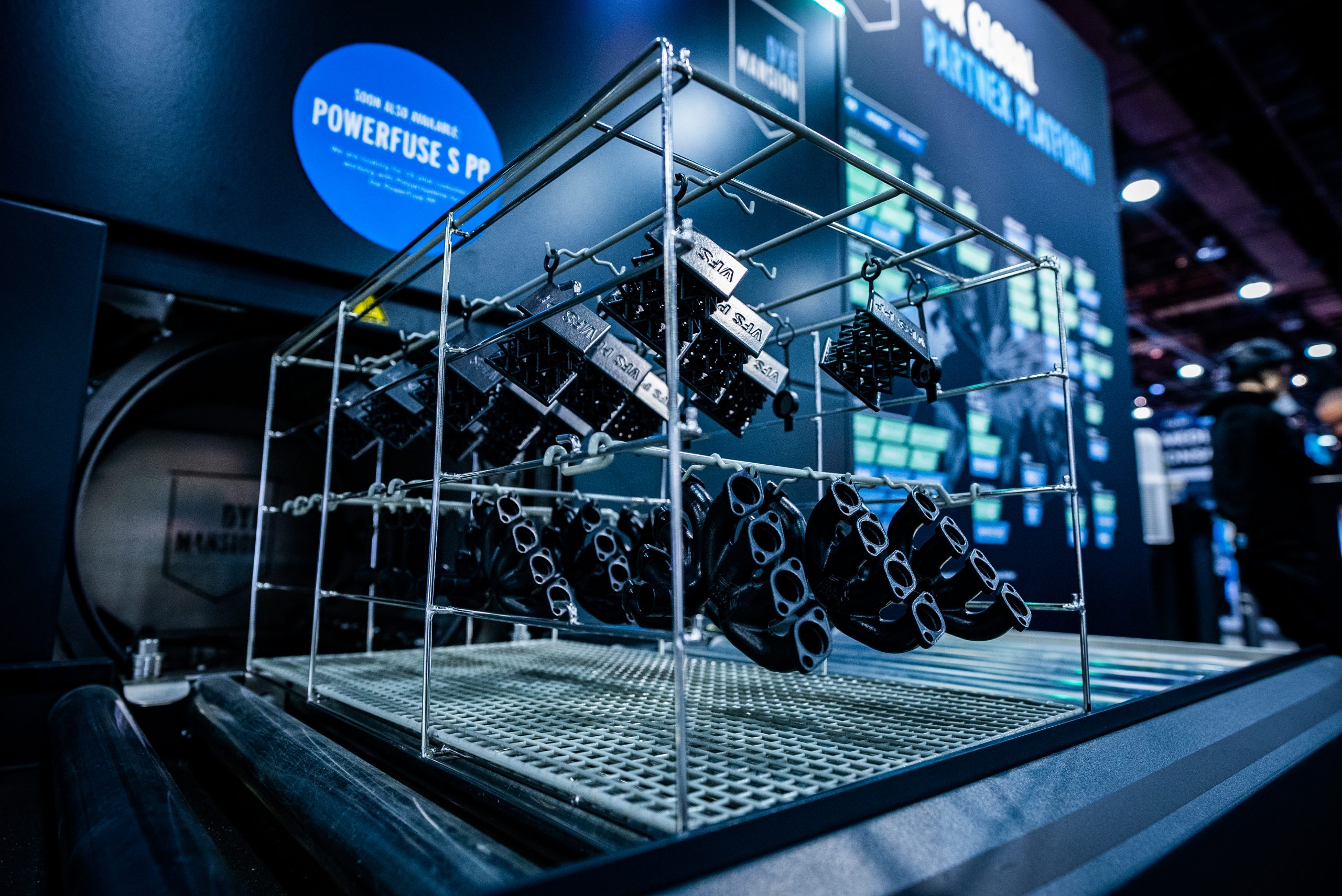

Flexible plastics such as Thermoplastic Polyurethane (TPU) and Polypropylene (PP) are gaining relevance and offer a variety of new applications. DyeMansion has therefore tuned their VaporFuse Surfacing technology of the Powerfuse S, making it compatible with Lubrizol’s ESTANE 3D TPU. Beyond that, DyeMansion, a post-processing specialist, is announcing the forthcoming release of the new Powerfuse S PP.

At Rapid in Detroit, visitors can learn more and see TPU parts which have been finished with the Powerfuse S and Polypropylene parts from the soon-to-be released Powerfuse S PP.

ANNOUNCING THE LAUNCH OF THE NEW POWERFUSE S PP

A SPECIAL VERSION OF THE POWERFUSE S AND THE FIRST-EVER SYSTEM TO

SMOOTH 3D-PRINTED PP

The preparations for the launch of this new solution are already in full swing.

Currently, DyeMansion is qualifying customers for the pilot phase. The system is to

be officially revealed at Formnext 2022 later this year. According to market experts

who have seen the first parts, the technology behind the Powerfuse S PP is already

achieving a PP surface quality standard suitable for industrial use today. Vapor

polishing improves the mechanical properties of polypropylene parts – the outcome

is sealed, washable surfaces that are visually and functionally on a par with

injection molded parts. This makes completely new applications possible.

“One of the biggest limitations in Additive Manufacturing is material availability. Enabling the industrial use of PP will be a big driver for further growth in our

industry. We are very happy that we found a way to provide injection molding like surfaces and enhanced properties through our Powerfuse S PP, and we are very much looking forward to seeing the first high-volume use cases soon”, says Felix

Ewald CEO and CO-Founder of DyeMansion.

The technical specifications of the special Powerfuse S PP are nearly identical to

the current Powerfuse S version. DyeMansion specially developed the solvent for

PP materials. It is green as well as bio-based and fulfills DyeMansion’s principle of

economic sustainability. This new solvent has already been successfully tested with

all common PP materials on the market so far from HP, BASF, EOS, ALM, Prodways,

AM Polymers or Covestro. Visitors can see parts for themselves at the DyeMansion

booth 1920 at Rapid in Detroit from May 17-19.

A NEW PROCESS FOR SMOOTHING AVAILABLE FOR THE POWERFUSE S:

Another big step for VaporFuse Surfacing is the compatibility with Lubrizol’s

ESTANE 3D TPU. This material is characterized by abrasion resistance and high

mechanical properties which tend to complicate traditional vapor polishing.

DyeMansion has been able to create a new program for their Powerfuse S system –

designed specifically for this TPU. This new program adds another TPU to

Powerfuse’s material portfolio alongside existing TPUs such as from BASF.

The brand-new process is available immediately, reducing surface roughness to a

minimum; sealing the surface of TPU parts, making them ready to use in fields like

Orthotics, automotive applications, and many more. At Rapid, visitors can see

first-hand one of the first applications using this material – finished with the

DyeMansion Print-to-Product workflow: the Quatro Prosthetic Sock from the

Colorado-based medical tech company Quorum.

A STRONG PRESENCE OF DYEMANSION’S POST-PROCESSING TECH AT RAPID 2022

Under the motto “We deliver the finishes your parts deserve”, DyeMansion is

proving once again this year at Rapid that finishing is not just about single surface

finishing products, but about providing users of industrial 3D-printing with a

complete, fully integrated workflow. In addition to the various surface finishing

solutions such as the Powershot S and the Powerfuse S, trade show visitors will

also be able to experience DyeMansion’s solutions for depowdering and dyeing “live

and in color.”

On May 18, DyeMansion had a joint presentation with their production partner

Stratasys Direct Manufacturing. “From the Racetrack to the Manufacturing Line: How to get beautiful high- performance parts in serial production (NASCAR case study)” is the title of the session where Head of Application Consulting Mike Schorr together with Kevin

Sheehy from Stratasys will give insights into an exciting automotive application. CATi and GoEngineer, two of the six North American Stratasys resellers of DyeMansion solutions, will exhibit at Rapid as well.

“I am delighted to welcome six new partners in the United States to the

DyeMansion Sales Partner platform. The consequent execution of our reseller centric go-to-market strategy is highly valued by our customers around the world.

Together with our partners, we make end-use part-specific consulting and the respective leading DyeMansion Print-to-Product workflow solutions available to all Additive Manufacturing users”, tells Kai Witter, Chief Customer Officer at DyeMansion.

Learn more about DyeMansion and visit www.dyemansion.com

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.