Dyndrite, provider of the Accelerated Computation Engine (ACE) and Application Development Kit (ADK) for the development of hardware and software for next-generation digital manufacturing, announced that UPM Additive Solutions, a leading supplier of metal build plates to the additive industry, has entered into an agreement to develop “smart” metal build plates for the 3D metal printing industry.

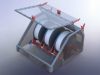

The build plate is an essential part of 3D metal printing, forming the basis for every part to be manufactured. However, most users in this field do not record key data that could reveal the life cycle and history of their build plates. Without this information, Laser Powder Bed Fusion (LPBF) is at increased risk for powder leveling, panel fatigue and warpage, which can lead to lost time and costly downtime.

The UPM Smart Build Plate service will support all major metal 3D printer OEMs, including Aconity, EOS, Renishaw and SLM Solutions, and is expected to launch in the third quarter of 2023.

“UPM is excited to partner with Dyndrite and its metal users to unlock the keys to build plate life”, said Chris Prue, UPM Additive Solutions. “Through data, we can put knowledge in the hands of the user to raise throughput and reduce failures. Build plate usage data helps customers understand and manage their usage and demand for plates to keep costs low while keeping inventory available to reduce downtime. Through smart build plates and a reliable supply chain, we can collectively mature and grow the industry.”

“For the AM production industry to scale we must develop new tools to enable it. By working with UPM and leveraging the power of machine data we can accelerate learning, improve predictability and grow,” said Harshil Goel, founder and CEO, Dyndrite. “Through insights of the data we allow users to make less risky decisions on their build plates to assure success.”

UPM currently offers subscription-based services to track building boards from manufacture to customer and through remanufacturing. Each plate is serialized and has accessible quality inspection data. Smart Build Plate customers can view the manufacturing data associated with each plate from the machine.

Find out more about Dyndrite at dyndrite.com.

For more information about UPM Additive Solutions, please visit upmet.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.