Commonly bioplastics like PLA were produced with the help of different chemical processes. Even if no mineral oil was used for the process it couldn’t be seen as green technology. These chemicals are harmful for the environment and very expensive to dispose. Carbios has now developed a new technique which is easier, cheaper and most important better for the environment!

PLA is often used in the food industry for packaging and different other products. But most of our readers will know PLA as a material used for FDM/FF 3D printing. It´s easy to work with and affordable.

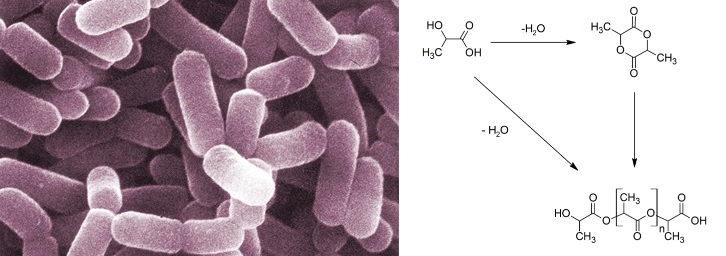

To make this eco friendly process possible Carbios has developed microbes that produce the PLA and could replace the harmful chemicals. The result is a 100% PLA polymer of high molecular weight (i.e. a long chain). With these technique Carbios could produce cheaper PLA because they replace the expensive chemicals in the production process. The researchers say that the same method could be used for the production of other plastics like PHA. The new technique was developed with the help of the French National Institute for Agricultural Research (INRA) and the Institute National Des Sciences Appliquées Toulouse (INSA). The same teams are working a method of endless recycling of PET plastic.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.