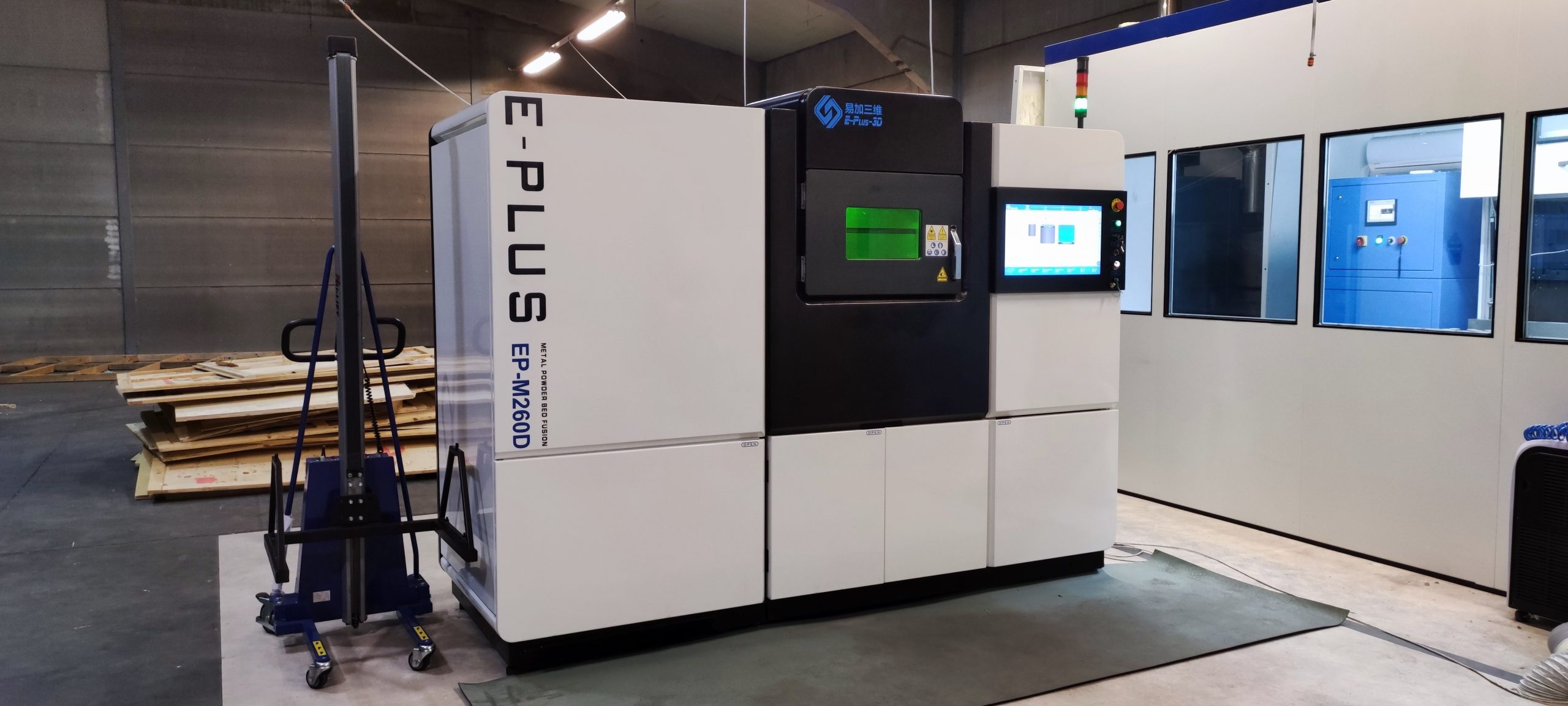

Early this year, Eplus3D installed another Metal 3D printer EP-M260 with dual laser for Metal Technics 3D (MT3D) in Kuurne, Belgium. This was the second time that Metal Technics 3D installed a metal 3D Printer from Eplus3D.

Metal Technics 3D is a metal 3D Printing company. It’s also a part of the Metal Technics Group (a big group of metalworking companies active in precision sheet metal and precision machining). Founded in 2015, Metal Technics 3D has 2 different machines with different build times and platform sizes to increase its flexibility and allow them to print both big series and small production runs with small lead times.

Metal Technics 3D chose a metal 3D printer EP-M250 from Eplus3D about two years ago. Now they chose another similar metal 3D printer EP-M260 from Eplus3D again. The following is a short interview with the Head of Engineering at Metal Technics 3D.

Eplus3D: “What makes you choose the second machine from Eplus3D again?”

MT3D: “Two years ago, we chose the first metal 3D printer EP-M250 from Eplus3D based on several factors. First of all, affordability. That machine is quite affordable and has a very nice building platform for its price. Second of all, after-sale service. We look for a machine with a perfect support team. Then we found Eplus3D. These supports are the main reason why we get the second machine from Eplus3D. This time we get this EP-M260 with dual laser. After almost three years with EP-M250, we are quite happy with, our parts are printed very well and the support is great.”

Eplus3D: “Why did you choose EP-M260 with dual lasers?”

MT3D: At the moment, we are printing quite high blocks. We started this project with EP-M250. Then we thought there was a lack of printing capacity, so we went to a bigger machine with two lasers, which doubles our productivity. In this case we can get a full building platform, with EP-M250, it will take around 13 days and with this machine EP-M260 dual laser, the full building platform will take around 6 days, so that’s half of the production time. It’s quite amazing.

Eplus3D: “What will you mainly do with Eplus3D printers?”

MT3D: “Well, as we are specializing at prototyping, we have a very diverse range of parts. As you can see, here some of them are conformal channels, or you have some prototypes. Because we have seen that there are many parts are designed to be printed, there are quite a lot of challenges on the parts, which is not easy to be milled, and we have to overcome the challenges here in the facilities, and the machine works great, so that helps us beat many challenges.”

Eplus3D: “What do you think of the partnership between Metal Technics 3D and Eplus3D?”

MT3D: “I think support quality is the one of the main reasons why we chose Eplus3D. It’s quite helpful for us, as a small company, if our printers are standing still for a few months, that could be devastating. So it’s quite reassuring to know that we can get someone on the line quite fast, and even some spare parts and accessories can be delivered very fast.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.