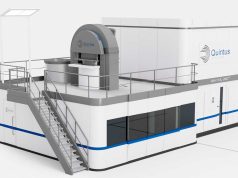

General Electric opened the Center for Additive Technology Advancement (CATA) near Pittsburgh to drive innovation and implementation of 3D printing technologies across the company. The center will focus on developing and implementing industrial applications for the company.

GE invests $ 39 million into their new facility that will initially employ 50 high-tech engineers in the fields of mechanic, electric, systems and software. The center will offer training and development in both design and applications. CATA is in line with the company’s Brilliant Factory concept and will combine lean manufacturing and optimal productivity with advanced software analytics in order to improve capabilities and usage of 3D printing for GE.

GE Chief Productivity Officer Philippe Cochet on the new center: “Today’s opening is strong evidence that GE is leading the digital transformation of industry, starting with a hub for the advancement of additive manufacturing techniques. The application of insights from digital connectivity in collaboration with intelligent devices will elevate the skills of our workforce, streamline productivity and enhance product development overall. This represents a new era of manufacturing.”

Along with the opening, GE launched the white paper “The Future Workforce: Advanced Manufacturing’s Impact on the Economy“, on the positive impact on jobs of advanced manufacturing and how it shapes the future of work. The paper highlights that advanced manufacturing accounts for 13% of all jobs in the United States, contributing $ 3.1 trillion to the economy.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.