The Girbau Group is a company that manufactures equipment for laundry services: specializing in manufacturing equipment for small and medium-sized laundromats and the industrial division, corresponding to laundry service providers with higher production requirements.

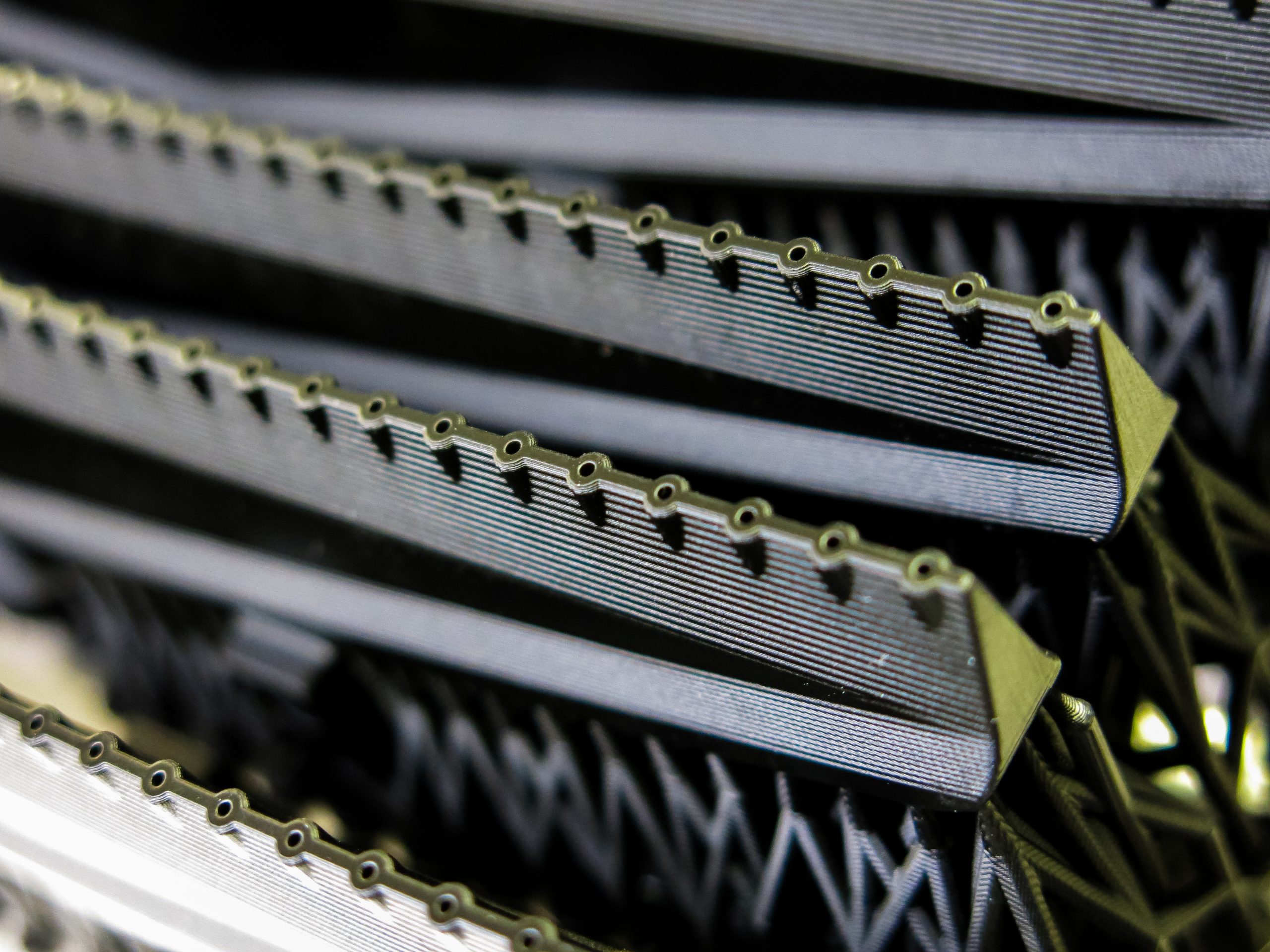

Girbau turned to additive manufacturing to create an innovative and cost-effective single solution part that would improve airflow and enhance their folding machines’ function. With the design freedom of additive manufacturing, and the help of Sculpteo, an online 3D printing service that offers a wide selection of high-performing 3D printing materials from BASF Forward AM, Girbau was able to optimize the internal geometry for better performance and integrative functions, effectively creating a better-designed part at a competitive price point.

Additive manufacturing is more and more used for the production of series and finished products, helping companies to overcome the constraints of traditional manufacturing. Sculpteo provides adapted manufacturing tools to streamline production, lower manufacturing barriers, and accelerate delivery of high-quality 3D printed products.

Find the full success story here

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.