Graphene 3D Lab, the company known for their Conductive Graphene Filament, has since released a variety of new materials including magnetic, water-soluble or the Flex Foam filament. Introducing Scorpion Flexible Nylon, they have added yet another material to their portfolio.

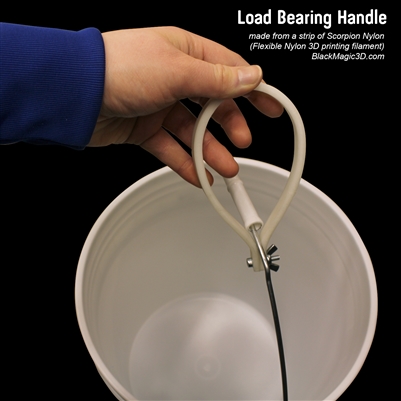

The material is said to feature outstanding resilience, as printed objects can handle repeated stress with ease while maintaining their shape. What make it stand out from other nylon material is its strong interlayer adhesion, which results in high durability in mechanical parts.  According to Graphene 3D it is also ideal for wearable designs due to its smooth surface texture and flexibility that increases with thinness of the material.

According to Graphene 3D it is also ideal for wearable designs due to its smooth surface texture and flexibility that increases with thinness of the material.

“Nylon attracted a lot of interest in the 3D printing industry due to its strength“, explained Graphene 3D Lab co-CEO, Daniel Stolyarov, “However the material has a problem with the interlayer adhesion being too weak. I am proud to say that our R&D team has successfully resolved this issue. I believe that our customers will truly love the Scorpion Flexible Nylon and look forward to receiving their feedback.”

“We are constantly looking to expand our product line to best meet the needs of our growing customer base,” Graphene 3D Lab Co-CEO Elena Polyakova adds. “We expect the addition of the Nylon filament to play an integral role in many different commercial markets. This filament can be readily produced in large quantities and we intend to ramp up production to satisfy our customer demand.”

Scorpion Flexible Nylon filament is available in the common diameters 1.75 mm and 3 mm through the company’s blackmagic3D webshop, Amazon and eBay. The 400 g spool comes with a price tag of $ 29.99.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.