The world of machining is completely different from the one that existed at the time the last AMB was held over four years ago. While the topic of “electromobility” has undergone an historic change in mechanical engineering, machining itself has progressed considerably. As the traditional long–line machining business dwindles, the potential inherent in the universal machine business continues to grow; particularly in the automotive, automation, mechanical engineering, die and mold industries, as well as in the aerospace, energy and medical technology sectors.

Innovative machining technology for all industries

To keep on top of this development, GROB has adapted its product range to reflect the market requirements and will use the 20th anniversary of the AMB to exhibit its latest technologies: from the G150 5–axis universal machining center with small GRC–R12 robot cell to the G440 4–axis universal machining center with PSS–R1800 rotary pallet storage system and the big G520F machining center for frame structure and chassis parts. With these exhibition highlights, GROB will once again demonstrate its machine concept with 4– axis and 5–axis machining centers offering nearly unlimited possibilities for milling and turning parts made of a wide variety of materials. No matter whether aerospace, mechanical engineering, toolmaking and mold design industries, automotive sector, or medical technology, GROB machining centers are optimized to meet the diverse requirements of all industries.

F series: crossover series for all important e–mobility components

The best example for the diversification of the GROB machine portfolio is the F series: A typical crossover series for all important e–mobility components. With the F series machines, GROB provides the ideal solution for lightweight construction components for electric drives (such as stator and battery housings, subframes or frame structure components) as well as compact and cost–effective machines whose larger work areas provide greater dynamics and the perfect conditions for machining aluminum. At the AMB, GROB will be presenting the G520F, a two–spindle machine for the parallel machining of two parts. It has an interference diameter of up to 1,200 mm in the B’–axis and 1,200 mm in the A’–axis (without restriction), with a maximum part length of up to 1,500 mm (with restricted axis swivel range).

GMP300 – additive manufacturing ‘made by GROB’

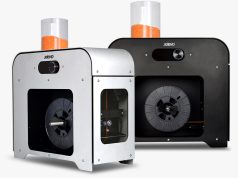

Additive manufacturing is becoming increasingly important in particular for prototype manufacturing, but also for small and medium–sized series components, for highly customizable components, or those with complex geometry. In light of this, GROB developed Liquid Metal Printing (LMP) for forward–looking, economical, as well as flexible additive manufacturing process that eliminates the disadvantages of traditional additive manufacturing in the metalworking sector. With the GMP300, GROB provides its customers with a production system for the manufacture of near–net–shape components in the Additive Manufacturing range for the first time.

It celebrated its premiere at the GROB in–house exhibition in May this year and will now enjoy its very first appearance at an international mechanical engineering exhibition. GROB involvement in the AMB Trend Lounge GROB will also be present at the Trend Lounge with Trend Area at the AMB, focusing on the topics of “Additive Manufacturing” and “Digitalization”.

On Tuesday, September 13, Dr. Martin Otter will give a talk on the topic of “GROB Liquid Metal Printing – economical production of near–net–shape components”, while Mr. Tobias Gödde will present the topic of “Digitalization solutions made by GROB – from maintenance through to the tool cycle” on Friday, September 16.

German Wankmiller, Chairman of the GROB Board & CEO, had this to say on the topic: “Even now, we already have an attractive offer of apps that allow our customers to monitor machines and perform various evaluations. This gives the customer maximum transparency across their entire production process. This is enhanced with simulation possibilities, solutions for unmanned operation, and a comprehensive package for service and maintenance.”

And GROB Chief Sales Officer Christian Müller adds: “Several years of absence from exhibitions have shown that there is no substitute for the direct exchange that is only possible in person. Taking part in the AMB exhibition for the seventh time, this year we will continue a long tradition of our company’s involvement in the exhibition”.

Find out more about GROB at grobgroup.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.