The EU initiative “Hyproline” aimed a building a working demonstration of a high performance AM production line for small series metal parts in order to strengthen the competitiveness of the European industry.

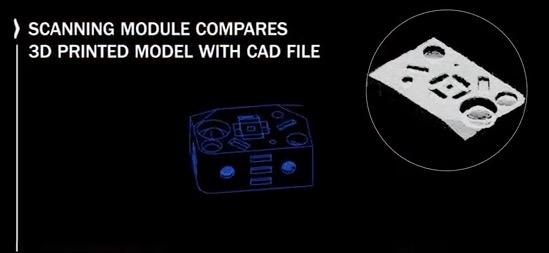

Launched in 2012, the project supported by Dutch research institution TNO, Digital Metal Höganäss, Swerea IVF, CCM, TranscenData and the University of Birmingham has been completed. Focused on the three metals stainless steel 316L, titanium and copper, the platform is designed to simultaneously print 100 parts on removable platforms arranged in a carrousel layout. The automate production and assembly line includes a 3D scanning module for measurement, comparing the printed products with the CAD file they are based on, as well as a laser module for polishing and removing excess material. An integrated robot picks and places non-finished parts during the process and extracts finished products.

TNO, who has developed the Print Valley system similar to Hyproline, will now further develop the additive manufacturing platform, as Frits Feenstra, senior project manager at TNO explains: “The concept was initially focused on SMEs in the electronics and aerospace industries, but has potential application in other industries that produce low volume, high precision metal parts. We are excited about further developing this manufacturing platform to enable fully integrated mass production of custom 3D printed products.”

The 3D scanning control system is based on CADfix, a software by International TechneGroup Limited (ITI) that inspects an analyses the prints by comparing them to CAD files. Mark Gammon from ITI explains: “CADfix is suitable for this type of additive manufacturing because of its flexible, closely linked representations of geometry, ranging from continuous CAD geometry to discrete facetted geometry, such as facets, slices or point clouds. Access to multiple forms of geometry enables CADfix to be applied effectively to all aspects of the AM geometry process chain. For the Hyproline platform, CADfix was comparing the point cloud scans to the as-designed CAD to extract the excess material to be removed by the laser processing stage. This endeavor was truly ground-breaking because of the high-speed of laser polishing of the metal parts, combined with 3D scanning to produce multiple, unique parts in the same run, on the same production line.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.