They had an ambitious goal – to industrialize additive manufacturing for both OEMs and SMEs. To reach it, partners from industry along with the Fraunhofer Institutes for Laser Technology ILT and for Production Technology IPT as well as RWTH Aachen University launched the BMBF joint project “IDEA – Industrialization of Digital Engineering and Additive Manufacturing” three years ago. As part of the project, they built two automated, additive production lines for metal 3D printing with exemplary performance to produce powerful high-end components such as those for gas turbines. And they did so successfully: In Berlin and Georgensgmünd, metal components have recently been produced with 3D printing, demonstrating how not only large corporations, but also SMEs can additively produce individualized components in medium batch sizes economically. Fraunhofer ILT’s Laser Power Bed Fusion (LPBF) process and digital engineering along the entire product development chain play an important role in optimizing the components.

“Mass producing additively manufactured (AM) components with metal 3D printing takes too long, cannot be automated and is far too expensive. Therefore, only aerospace or medical technology groups can afford this luxury.”

Eleven industrial companies and four research institutes from Aachen have refuted the argument by looking at the AM process chain in its entirety within the IDEA project, completed in October 2022. Funded as part of the BMBF’s “Line integration of additive manufacturing processes (LAF)” funding initiative, the project consortium developed a large-scale industrial pilot production line at the Siemens Energy gas turbine plant in Berlin and a production line for SMEs at toolcraft AG in Georgensgmünd. The digital twin of the factory, developed for SMEs and large-scale series production, was able to significantly reduce product costs even before construction and operation.

Siemens Energy and toolcraft: Lesson learned for further steps

After intensively developing and implementing many sub-processes along the additive manufacturing chain, the partners created two automated, modular production lines to demonstrate the maturity of additive manufacturing as an industrial production technology. That shall encourage manufacturing companies to use digital additive manufacturing in series production. The positive feedback from the operators of the lines proves that individual mid-series products can be mass-produced using Laser Power Bed Fusion (LPBF).

According to Julius Schurb, IDEA project manager, from the Siemens Energy gas turbine plant in Berlin: “We were able to demonstrate for our demonstrator component, a turbine guide vane, that the planned reductions in development and throughput times of around 50 percent can be achieved by taking a holistic view of the production chain from design to finished product. These results will enable us to further advance the industrialization of additive manufacturing and offer key components of our gas turbines at competitive costs, even in small quantities.”

However, metallic 3D printing is not only an option for large companies, but also for small and medium-sized enterprises. This statement can be backed up by toolcraft, a medium-sized company that uses additive manufacturing processes for series production. This company specializes in the production of tools and injection molded parts as well as precision components and assemblies for the aerospace industry, semiconductor industry and medical technology.

“In the IDEA project, we succeeded in completing important development steps, including being able to better map an integrated, end-to-end manufacturing chain made up of sub-processes,” emphasizes Markus Langer, head of Digital Transformation / Technology and Development Promotion at toolcraft. He provides an overview of the project results: “Manual work steps were substituted by automation solutions, which helped us achieve higher process stability and quality. In order to use real data virtually, we also need to highlight digitalization, which must be considered globally for the production of additively manufactured components. It was also important, for example, to use VR goggles to transfer analog data, as further developed in IDEA, to digital work plans, to work and test instructions and interactive training. This way we could accompany the employees in the highly complex task environment in the best possible manner.”

Interdisciplinary collaboration: Achieving the goal together

The interdisciplinary composition of the IDEA project team brought together experts in turbomachinery, digitalization, automation, aircraft technology, post-processing, laser and 3D printing technology, among others – this mixture proved to be a key factor for the project’s success. Users did not have to start from scratch on the project. This was ensured, for example, by the experts from Fraunhofer ILT in Aachen, who contributed their expertise in the field of LPBF developed in previous research projects to the consortium.

Component quality under control with process control

Thomas Laag, research associate at Fraunhofer ILT explains the importance of process control: “Since the aerospace industry has very high safety standards, the application of laser beam melting sinks or swims with intensive quality assurance along the process chain. Within IDEA, the partners focused particularly on rule-based monitoring of the powder condition, robust process qualification of multi-laser machines, and the further development of solutions for automated process monitoring.”

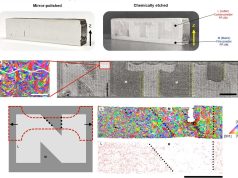

Fraunhofer ILT developed a process control system with pulsed laser radiation for LPBF, a system that can improve the detail resolution and prevent fewer shape deviations. It also reduces the effort required for post-processing and makes it possible, e.g. to manufacture complex geometries that have not only greater detail resolution, but also higher combustion efficiency.

In addition, a novel imaging monitoring system was developed and evaluated at Fraunhofer ILT. A high-resolution stereo camera can detect process instabilities such as component distortion or powder bed defects. Since the camera system is mounted on the coater, it can in principle also be retrofitted to existing machines. In cooperation with the partner Jenoptik, Fraunhofer ILT demonstrated an AI-based evaluation of the measurement data.

Focus on the entire physical and digital process chain

Despite their different tasks, the two production lines have many things in common. The focus of IDEA was to digitally transform the entire process chain under the heading of digital engineering: Targeted automation, in conjunction with digital twins and modern product control systems, ensures that all relevant production data is recorded and used continuously. The lines thus differ significantly from conventional 3D printing systems since the latter have largely isolated process steps and require many manual interventions, both of which can easily lead to “trial and error” production and high component costs.

“In the field of additive manufacturing, the digital twin is revolutionizing processes along the entire value chain,” highlights Dr. Karsten Heuser, VP of Additive Manufacturing at Siemens Digital Industries. “As a virtual image of the additive component, production process or performance, it enables us to seamlessly link the individual process steps. By using the digital twin, we could consistently increase the efficiency of the two industrial lines, minimize the error rate, as well as shorten the development cycles.”

A special feature of both production lines is the both physical and digital mapping of the additive process chain. This includes automated measurement methods for component geometry monitoring, the additive repair of turbine guide vanes and the automated finishing of additively manufactured components.

Fraunhofer ILT at formnext 2022

Interested parties can find out more about ILT’s current research activities in LPBF at formnext 2022 in Frankfurt am Main from November 15 to 18, 2022, at the Fraunhofer ILT booth B32 in Hall 11.0.

According to Laag: “We will show various interesting insights into new developments and applications of LPBF technology.”

The “IDEA – Industrialization of Digital Engineering and Additive Manufacturing” project, which runs from April 1, 2019 to October 31, 2022, has been funded by the German Federal Ministry of Education and Research BMBF (Photonik Forschung Deutschland). IDEA is a part of the “Line integration of additive manufacturing processes (LAF)” initiative, funded with 27.5 million euros.

For more information about Fraunhofer ILT, please visit fraunhofer.de.

To learn more about RWTH Aachen University, please visit rwth-aachen.de.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.