As part of a joint study between the Institute for Production Engineering and Photonic Technologies (IFT) at TU Wien and the research company FOTEC, the effects of varying process parameters on the geometric and thermomechanical properties of additively manufactured parts were investigated.

As part of the interdisciplinary cooperation project Ad-Proc-Add, Dipl.-Ing. Dimitrii Nikolaev and Dipl.-Ing. Ismail Yavuz, under the leadership of Univ.-Prof. Dr. Friedrich Bleicher from the Institute for Production Engineering and Photonic Technologies (IFT) at TU Wien, investigated the energy efficiency of post-processing methods and evaluated the possibility of vibration-assisted drilling and machine hammer peening (MHP) on components produced using additive manufacturing.

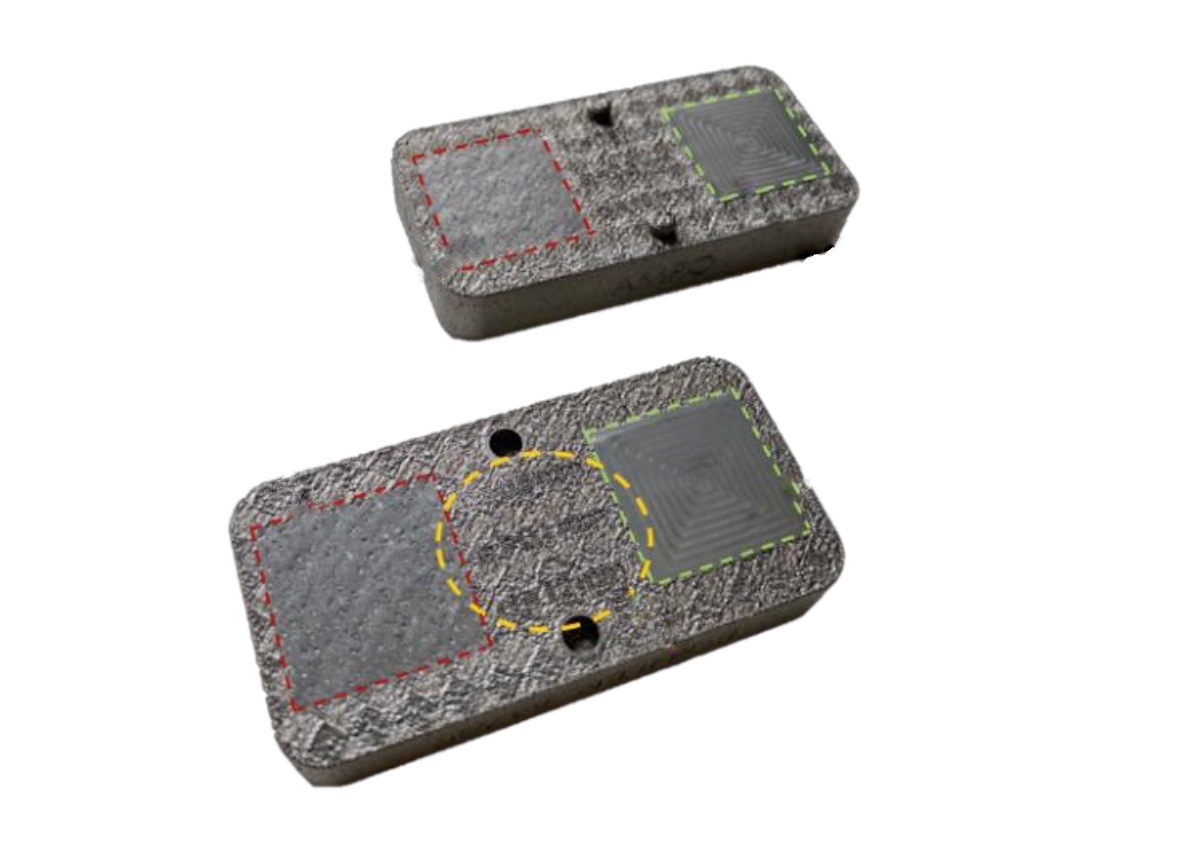

The expert team, in collaboration with the research and technology transfer company FOTEC, confirmed through the study that vibration-assisted drilling can be successfully applied to additively manufactured components to reduce cutting force by 30% compared to conventional drilling when working with martensitic steel alloys. Additionally, machine hammer peening showed effective surface smoothing and can be considered a recommended treatment for functional surfaces of additively manufactured parts.

The researchers also found that a minimum material thickness of 3.5 mm is required for freestanding surfaces of heat-treated AlSi10Mg components produced using Laser Powder Bed Fusion (LPBF) to avoid plastic deformation. When using a smaller impact head and a parameter set with more distant impacts, a thickness of 3 mm may be sufficient. However, thin-walled components with wall thicknesses below 3 mm should not undergo MHP treatment due to the high risk of plastic deformation.

The results of this study provide important insights for developing more effective and energy-efficient post-processing methods for additively manufactured parts, as well as for optimising process parameters and material properties. These findings can assist system and service providers in developing new products with enhanced functionality and enable end-users to implement additive-subtractive process chains with higher productivity and increased economic and environmental efficiency.

The project’s final report can be obtained through the Forschungskuratorium Maschinenbau (FKM) e. V.. Postal address: Lyoner Str. 18, 60528 Frankfurt am Main, Germany,

Email: info@fkm-net.de, Phone: +49 69 6603 1352.

Further information is also available on the project website: www.ad-proc-add.eu

Contact

DI Benjamin Losert, Projektmanager Mechatronik-Cluster ecoplus.

Niederösterreichs Wirtschaftsagentur GmbH

Niederösterreich-Ring 2, Haus A, 3100 St. Pölten

E-Mail: b.losert@ecoplus.at, Tel.: +43 2742 9000-19669

About ecoplus

As privately run agency with decades of experience, with a highly-specialized team and an expansive network, we offer tailored services to your business. With 16 business parks throughout Lower Austria, we also provide first-class business locations for companies. Our technopols focus on building up technology oriented business locations near existing research and educational facilities. We can also help find access to regional funding and give you a competitive advantage through innovative cooperation’s projects in clusters & platforms that we manage. You can visit the new House of Digitalization in Tulln, which is the flagship project of Lower Austria’s digitalization strategy. In addition, companies from Lower Austrian and abroad can count on our support through the Export / Expat & Relocation Service.

Funding organisations

Federal Ministry for Economic Affairs and Climate Action, German Federation of Industrial Research Associations eV, Collective Research Networking (BMWK/AiF-CORNET), Austrian Funding Agency (FFG), Confederation Switzerland and Flanders Agency for Innovation & Entrepreneurship (VLAIO).

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.