In the field of vacuum technology outgassing materials are forbidden because they bring along attributes which make it difficult to achieve desired vacuum quality. Outgassing materials release molecules in gaseous form which can contaminate prime components or diffuse into machine parts modifying them against their designed purposes.

Metals have primarily played a key role in the design of parts destined for applications in vacuum technology because when well treated they do not outgas. Most polymers however do outgas. This is an inherent feature in polymeric materials because they are essentially made from chemical species with tendencies to evaporate under appropriate temperature and pressure conditions.

One of the attributes of PEEK is its low outgassing behaviour even at relatively high temperatures.

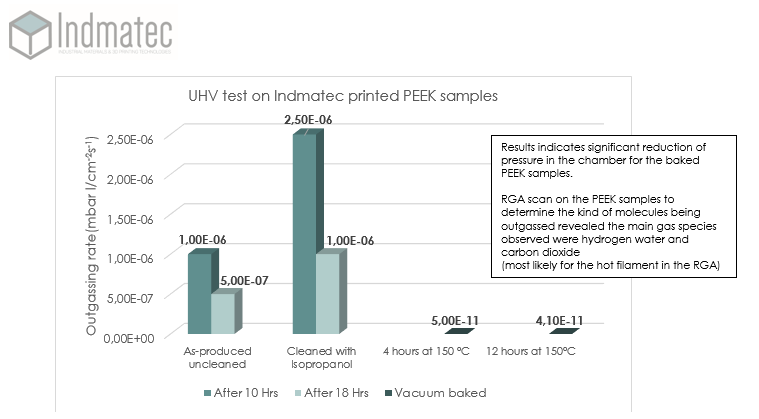

Vacuum tests conducted on PEEK parts fabricated using Indmatec 3D printing technology and Indmatec PEEK filament material showed an outgassing rate of 5×10-7 mbar l/cm-2 s-1 after 18 hours in vacuum. To bring this data into context, fact is that the PEEK material in its as-3D printed state meets the material requirement for high vacuum applications. When baked for 12 hours at 150 °C prior to testing in vacuum condition, the 3D printed PEEK part exhibits outgassing rate of 4.1×10-11 mbar l/cm-2 s-1; a value falling well within the ultra high to extremely high vacuum range.

This quality of data together with PEEK’s resistance to radiation damage extends Indmatec’s 3D printing technology to applications in space exploration where light-weight materials capable of enduring the demanding requirements for research in space environment are sought.

Vacuum technology applicable PEEK parts fabricated using Indmatec 3D printer

Contact:

Brando Okolo (PhD)

brando.okolo@indmatec.com

Acknowledgement:

We appreciate Mr. Andy Stallwood of Diamond Light Source Ltd for the vacuum tests.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.