Intech Additive Solutions, an end-to-end solutions provider in metal additive manufacturing systems, design for AM and AM software, collaborated with Bhabha Atomic Research Centre (BARC) to successfully design and 3D print miniature metal components.

Miniature metal components play a very vital role in several critical applications in miniature robotics (bio-robotics), especially in field of customized electroporation devices such as drug delivery, pre-treatment of food, cosmetic therapy of skin, etc.

Given their size and complexities, manufacturing, output management and timely deliveries of these components through conventional methods pose a never-ending challenge. Metal 3D printing technology therefore becomes an ideal ally in such scenarios for manufacturing miniatures, intricate and semi-sculptured components by virtue of its design and the economically feasible solutions.

This was made possible with Intech Additive’s iFusion LF series of printers, that boast of their capability to manufacture small to large metal parts for multiple industrial applications.

The iFusion LF series of metal printers are designed to achieve high build rates, manage optimized cost-per-part (CPP) and cost-effective manufacturing. Automated powder handling, part removal and powder sieving are a few of its comprehensive features specifically designed to meet the needs of higher productivity and serial production prevalent in the industry. iFusion LF1 is a large-format LPBF Metal 3D Printer amongst the iFusion range in Intech Additive’s portfolio with one of the largest in-class build volumes of 450mm X 450mm X 450mm.

Equipped with Intech’s very own software AMOptoMet and AMBuilder, it was possible to achieve “first-time-right” scenario while printing the miniature components.

AMOptoMet is a first-of-its-kind and the world’s only new alloy parameter development software. It is a software suite for optimization, tuned for calculating and optimizing the process parameters of a given alloy for the Laser Powder Bed Fusion (LPBF) technology. AMBuilder is a build processing software with an intuitive workflow and a host of intelligent features. AMBuilder’s optimal orientation of parts, support generation, and path generation assisted in the build preparation of the miniature component.

BARC provided the initial designs of the miniature components for possible adaption to the AM process. Intech’s team of DfAM experts suggested and implemented further design modifications for the optimum functioning of the components.

“In my opinion, engineers at Intech have good acumen of technical brilliance, sense of practicality and leadership. I have observed that the engineers do follow ‘first principle thinking’, which is very essential for any indigenous out-of-the-box solution for new technology. I am proud to say that within a short span of 6 months, engineers of Intech have achieved the pinnacle of authentic product-oriented manufacturing with due persistence and passion.”, said Dr. Debanik Roy, Scientist, Division of Remote Handling & Robotics, Bhabha Atomic Research Centre, in his appreciation letter to Intech Additive.

Metal 3D Printed Miniature Metal Component

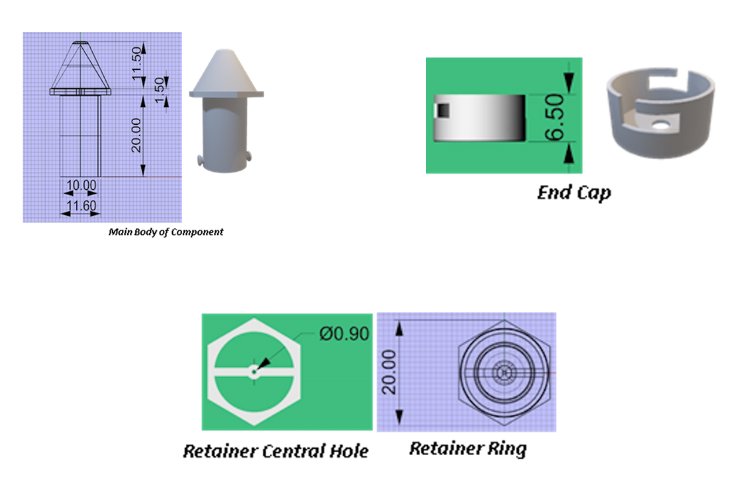

The Metal 3D Printed monolithic miniature component has an overall length of 33 mm with a cylindrical housing (OD: 11.6 mm; ID: 10 mm) and a tapered front. The crucial part of the manufacturing process was in the printing of a tiny portion, the “retainer ring”, having a thickness of 1.5 mm and a central hole of diameter 0.9 mm. The crux of this entire ensemble manufacturing is the printing of the retainer ring. Ensuring the workability of the printed retainer ring is essential for the actuation of the component.

This component was to be assembled with another part, the “end-cover”, having a height of 6.5 mm. The completed assembly of the component is now fully functional and can be used for a variety of applications post further instrumentation.

Following are the part dimensions:

● Length – 33 mm

● Cylindrical housing OD – 11.6 mm

● Cylindrical housing ID – 10 mm

● Retainer ring thickness – 1.5 mm

Metal 3D Printing Statistics:

| Description | AMBOTS |

| Material | SS 316L |

| Layer Thickness | 40 microns |

| Build Time | 3 hours |

For more information about Intech Additive Solutions, please visit intechadditive.com.

To learn more about Bhabha Atomic Research Centre, please visit www.barc.gov.in.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.