Italdesign, a leading design and engineering company, has used Stratasys’ 3DFashion technology to develop the innovative Climb-E concept vehicle. This involved using 3D printing directly on microfibers to push the aesthetic and functional boundaries of the new concept.

Developed in collaboration with Schindler and Politecnico di Torino, the concept combines travel and living, challenging traditional notions of automotive, living, working and entertainment spaces. The interior of the Climb-E had to be carefully designed to fulfill all roles.

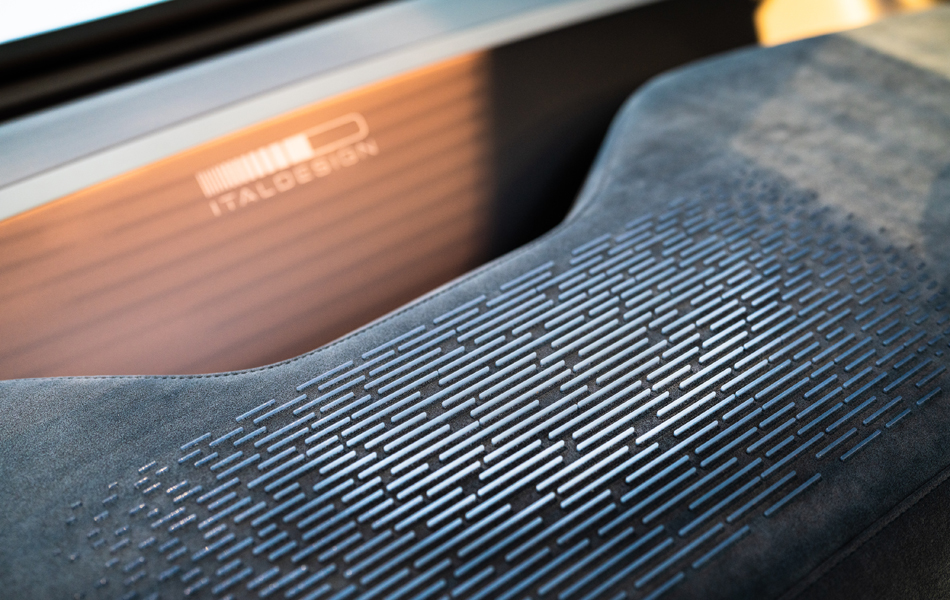

Italdesign used Stratasys’ 3DFashion platform, including design software and the J850 TechStyle 3D printer, to create the stunning interior design of its latest creation. The 3DFashion technology allows designers to print on textiles in over 600,000 colors with different shore values, simulating different textures and surfaces.

“When the Climb-E project was born I immediately thought that Stratasys technology would be perfect for the vehicle interiors,” says Gilardi. “Through its ability to uniquely combine transparencies and special chromatic effects, the 3DFashion technology can be used to convey a sense of real, and at the same time virtual, color. Because colors can change depending on the lighting and the point of view it is particularly able to integrate the different worlds of automotive design and fashion.”

The graphics on the rear horizontal Alcantara backrest surfaces were printed directly onto the microfibers using Stratasys’ J850 TechStyle 3D printer. Gilardi sees two interesting uses for Stratasys’ 3DFashion technology in the automotive sector: prototyping with 3D-printed textures and customization, such as 3D printing on translucent fabric for innovative backlighting effects.

Adds Gilardi: “I see two very interesting uses for the Stratasys 3DFashion technology in automotive. Firstly, for the production of prototypes, with the reduced lead times and costs, that also brings 3D printed textures to complement standard coating materials.

“Secondly, customization. For example, 3D printing onto mesh through which light can shine can create very innovative effects with backlighting – an area ripe for experimentation! In future, combining 3D printing onto textiles with embedded electronics could give novel ways of interacting with the functions of the space,” she concludes.

Find out more about Italdesign at italdesign.it.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.