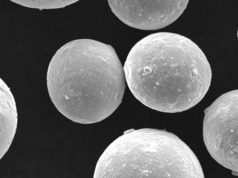

Dutch 3D printing material manufacturer Liqcreate has added a new ultra-soft elastic engineering resin to its materials portfolio: Elastomer-X. This resin, is designed to be one of the softest 3D-printing elastomer resins in the market. With a Shore A hardness of just 43 it is similar to soft TPU’s and silicone materials. The high elongation, good tear strength and low shore A hardness makes it ideal for manufacturing elastic parts and soft digital lattice structures.

Liqcreate’s softest polymer yet

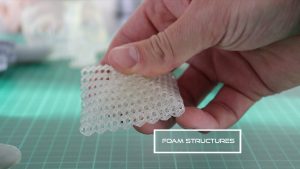

Liqcreate’s new TPU-like photopolymer resin, Elastomer-X is designed to be compatible with open SLA, DLP, and MSLA systems in the 385-420 nm range. The material itself is characterized by its excellent elongation, good tear strength and elastomeric properties, which are displayed in the table below. The combination of these properties makes the resin an excellent choice for the production of digital lattice foams, soft end of arm tooling (EOAT) for robots, grommets, bellows and elastic industrial parts.

Three different Liqcreate flexible & elastic photopolymer 3D-printing resins

With the addition of Elastomer-X, Liqcreate offers three commercial flexible or elastic resins under its own brand. All three resins cover a different application area. Premium Flex is the most rigid of the three materials. With a Shore A 65 it is still flexible and soft and is ideal for prototyping purposes and yields faster printing speeds compared to the other resins. Flexible-X a slightly softer resin (Shore A 55), it offers a better degree of softness with a good tear strength to cover more engineering type applications. Lastly the newly added resin Elastomer-X is the softest material in its range with a Shore A of 43, this resin can be colored to almost any color and has a good tear strength, aiming for the even softer applications where normally a soft TPU or silicone is used. With its tear strength of 10 – 12 kN/m it is one of the most tear resistant materials in its class of low Shore A photopolymer 3D-printing resins.

Applications of Liqcreate flexible photopolymer resins

There are plenty of applications that would benefit from an extremely soft resin with good tear strength. For example, the endless opportunities with making soft lattice structures that can mimic foams! Next to foams, there is the robotic industry where they can benefit from soft silicone-like materials to mimic skin, or make soft robot grippers and fingers. From the industrial perspective, the soft end of arm tooling (EOAT) industry can now produce extremely soft grippers. Furthermore, applications like grommets, bellows and general elastic industrial parts can be manufactured with support of Liqcreate Elastomer-X resin.

A growing resin portfolio for engineering, jewelry and dental applications

Liqcreate specializes in resin development and production for SLA, MSLA, and DLP 3D printers. Clients utilize the firm’s current material portfolio within various applications, including the fabrication of prototype and end-use parts in the medical, industrial, automotive, and consumer goods industries. At present, the company’s range includes its premium, creative, engineering, castable, and general purpose resins, with each featuring different qualities to address a specific target market. Liqcreate’s general-purpose polymers, for example, provide users with a high level of print accuracy and a smooth finish.

Over the past years, Liqcreate has expanded its portfolio, launching the dental-oriented Liqcreate Premium model, Dental Model Pro, Gingiva Mask as well as wax-based casting resins. In the engineering field, MSLA focused Premium Flex and Tough resins resin with increased print speed were developed. For the most rugged applications, Liqcreate introduced the Tough-X, Flexible-X and Composite-X photopolymers, which feature strong impact-resistance and rebound properties. With the launch of its Composite-X material in 2021, Liqcreate has added an ultra-stiff resin to its portfolio that’s completely different from the rest of its range. The polymer is reinforced by micro-nano particles, providing it with excellent strength characteristics, and once heated, it reacts by becoming significantly more rigid than conventional polymers.

Designing the ideal material for your application

In addition to marketing its set material range under the Liqcreate brand, Liqcreate also offers to develop customized resins for clients created for a specific application. As part of the service, customers can request adjustments to a given polymer’s properties, such as its print speed, color, or mechanical properties, to ensure it prints perfectly on their chosen platform. Within the range of flexible and elastic resins, there are options to develop materials varying from a Shore A hardness from 30 to 100 on request. Once Liqcreate has started formulating the novel polymer on request of a customer, it then produces samples for customers to assess as well as system parameters, before the final product is eventually shipped.

Given that Liqcreate is an independent resin manufacturer with R&D and manufacturing facilities, it’s also able to rapidly scale its production where needed. Due to the independent nature of the company, there is little to no competition or conflict when working with 3D printer hardware manufactures and other companies to develop their own 3D-printing resin product line. Allowing them to work quickly and getting their resins to market in quantities that won’t keep their clients waiting.

For more information about Liqcreate, please visit www.liqcreate.com and find out more about Liqcreate’s material portfolio by visiting its dedicated website.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.