Scientists at Lawrence Livermore National Laboratory (LLNL) and UC Santa Cruz have successfully 3D printed supercapacitors using an ultra-lightweight graphene gel. This achievement allows for unconstrained and new designs of highly efficient energy storage systems for smartphones, wearables, implantable devices, electric cars and wireless sensors.

February 11, 2016: “This breaks through the limitations of what 2D manufacturing can do,” said engineer Cheng Zhu, lead author of the paper published in the journal Nano Letters. “We can fabricate a large range of 3D architectures. In a phone (for instance) you would only need to leave a small area for energy storage. The geometry can be very complex.”

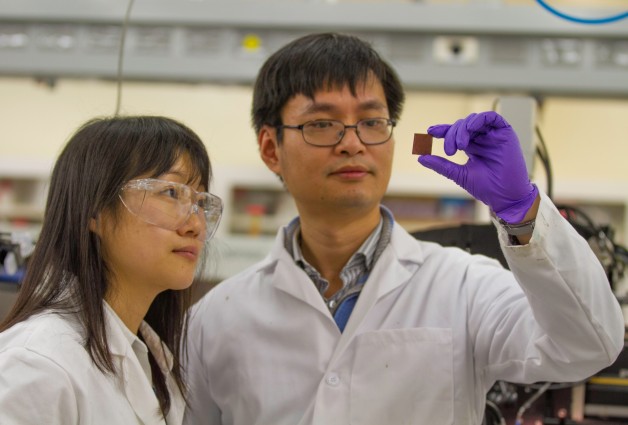

LLNL has created the supercapacitors using a graphene-oxide composite ink in a process called direct-ink-writing. These ultra-lightweigt electrodes are able to retain the same energy as electrodes 10 to 100 times thinner. Moreover, they charge incredibly fast and are capable of nearly fully retaining their energy capacity after 10,000 consecutive charging and discharging cycles.

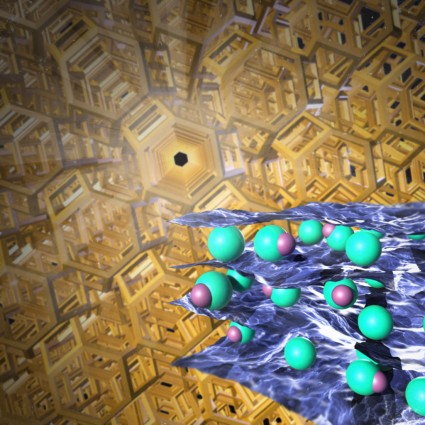

Compared to carbon-based materials, graphene-based inks have a more lightweight surface area and properties, better elasticity and superior electrical conductivity.

Eric Duoss, LLNL Materials Engineer explainded: “Additively manufactured 3D architectures for energy storage will improve energy and power characteristics for supercapacitors, enabling lightweight, miniaturized power sources. Graphene is a really incredible material because it is essentially a single atomic layer that can be created from graphite. Because of its structure and crystalline arrangement, it has really phenomenal capabilities.”

The researchers believe that these novel 3D printed supercapacitors will be used to create unique high-performance electronics, that are not possible using other methods, such as fully customised smartphones and paper-based or foldable devices.

June 20, 2016: Update – Researchers Improve Performance of 3D Printed Supercapacitors

The research team has recently come up with a method to double the performance of their 3D printed graphene-based supercapacitors. By sandwiching lithium ion and perchlorate into between the layers of graphene in aerogel electrodes, the capacity of the electrodes had been improved substantially.

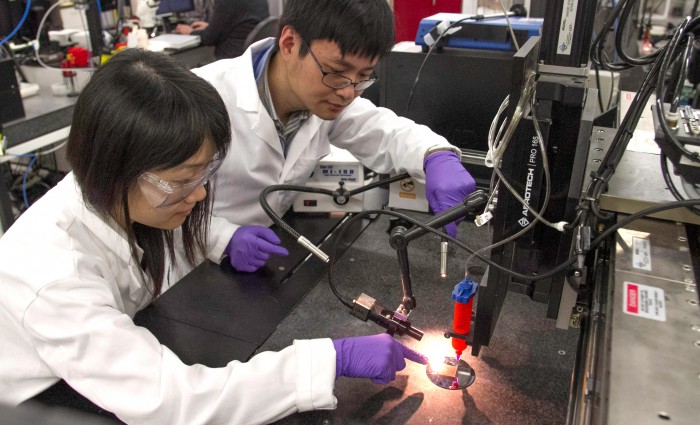

The method involves two ion-intercalation steps (lithium-ion intercalation and perchlorate-ion intercalation), followed by hydrolysis of perchlorate ion intercalation compounds.

“This two-step electrochemical process increases the surface area of graphene-based materials for charge storage, as well as the number of pseudo-capacitive sites that contribute additional storage capacity,” explains Fang Qian, LLNL material scientist and paper co-author.

The findings contribute to creating more powerful supercapacitors with complex architecture for custom-built electronic devices.

You can access the study titled “Ion Intercalation Induced Capacitance Improvement for Graphene-Based Supercapacitor Electrodes” here.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.