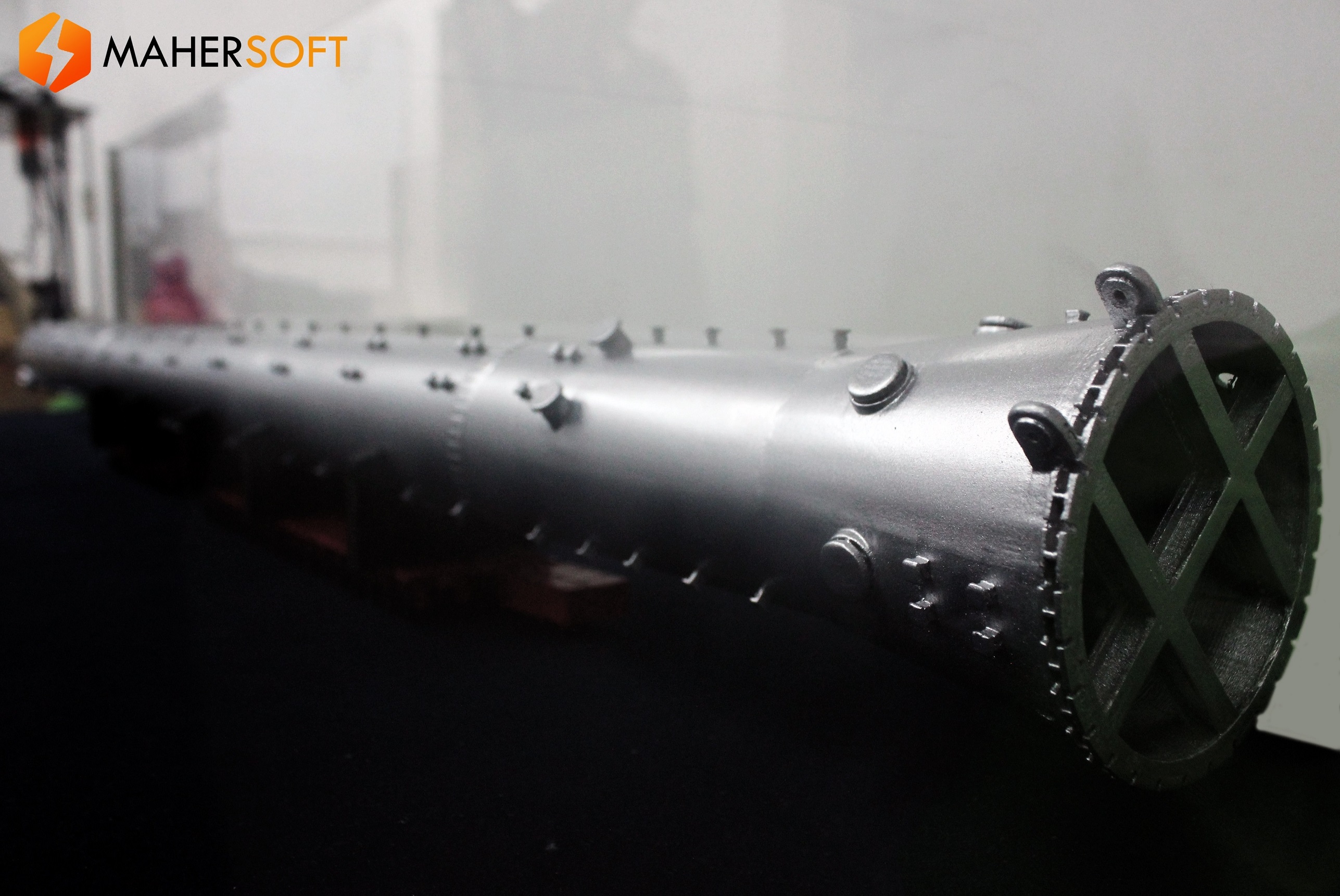

How we 3D printed a 1.3m long miniature model of a heavy transport equipment used for carrying heavy lifts in petroleum /refinery industry.

A leading transport services company which specializes in transporting super heavy structures, alternate heavy lifting approached us with the idea of 3D Printing a scaled model of a 115 m long heavy transport equipment used to carry heavy lifts.

The project was really challenging since we had to prepare the 1.3 m long scaled model into smaller parts to make 3D printable on our Indie Desktop 3D Printer. The scaled model was 3D printed with 14 separate pieces , all of which with heights ranging between 10 – 15 cms and another 120 smaller parts which includes equipment wheels, lever & base.

It took us approximately 3 weeks to complete the whole model which involved more than 3-4 days of re-modelling to prepare the files for 3D Printing, 140 hours of printing & one week of post processing.

The post processing of the model was really challenging phase since certain pieces were printed and painted separately, which were later glued together without any seam line in the final model. The end result is a scaled model of the equipment that would be ideal for displaying to the client.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.