Maker Joonas from the YouTube channel “Let’s Print” shows in a video how he builds a shredder with the help of a 3D printer.

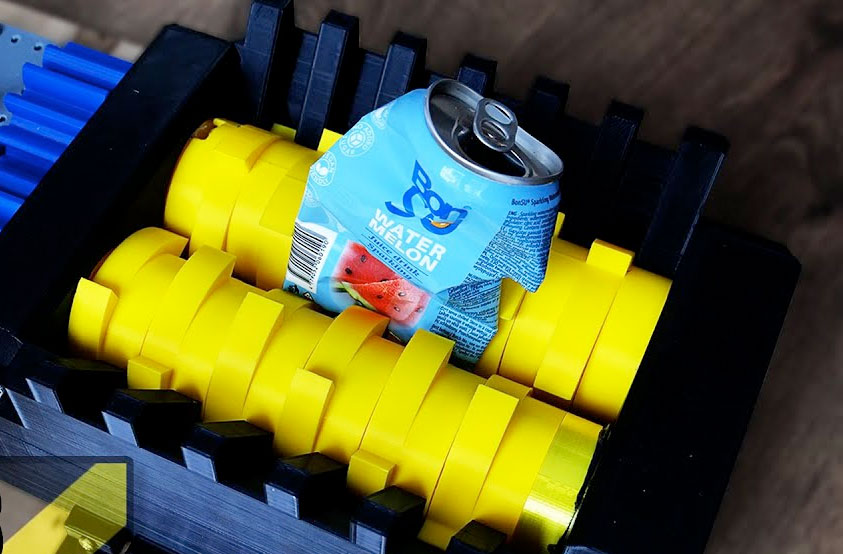

The DIY shredder is built like the large metal shredders you see in viral videos. The parts are pulled in with counter-rotating drums and torn into small pieces by strong teeth. So as far as that goes, there’s not much difference from conventional shredders.

But where industry uses large drums with hardened metal teeth, Joonas opted for a more cost-effective option: Using his fleet of 3D printers, he not only made the drums and teeth, but also the entire body of the shredder, as well as all the gears. The only component, apart from the motor and the screws, that is not 3D-printed are two aluminum profiles on which the teeth are mounted.

The machine is powered by a brushed DC motor, which is set to a sufficient torque using a multi-stage gearbox.

During his tests, the Maker didn’t miss a chance to experiment with his new design. He shredded some old vegetables or paper, and other more unusual items, such as a rock-hard cheeseburger, disappeared.

In the course of the tests, however, it became clear that the self-built shredder still needed some further development. With harder objects, such as an aluminum can or PLA scraps, the gearbox began to wear down and, slowly but surely, break off its teeth. Whereas the aluminum can already caused the drums to stop when it was pulled in, the PLA parts were pulled through, but were broken at most, so they were not crushed.

Nevertheless, it can be assumed that the principle of the 3D-printed shredder works, but there is still a bit of room for improvement in the right places.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.