Materialise introduces 3D printing innovations that increase productivity and efficiency in the 3D printing process. While technological improvements and material advances are driving the development of new applications, industrial print factories are looking for ways to raise output while reducing costs. Meanwhile 3D printing service bureaus are operating in an increasingly cost-competitive environment. At Formnext, Materialise presents software innovations that will help companies to scale their operations, use resources more efficiently, and reduce costs.

With the introduction of Magics 23, Materialise focuses on improved ease-of-use and giving users more control. The new Materialise Magics version provides improved automatic support generation and integrated simulation capabilities for metal 3D printing. In addition, Materialise announces an extension of its 3D printing services portfolio with new materials that support high quality prototypes and accelerate the adoption of additive manufacturing in the automotive, aerospace and consumer goods industries.

Materialise Magics 23: more powerful, better integration

With Magics 23, the latest release of the company’s data and build preparation software, Materialise introduces innovations to increase productivity and efficiency. By offering users more control and better integrated features, they can process large data sets faster; spend less time on data preparation; and enjoy reduced powder consumption. Users can easily create self-supporting honeycomb structures, preview and analyze the structure and get full control over its orientation on the build platform. Part quality is improved using fillets, which can be generated on a single edge.

Materialise Magics 23 also introduces Data Matrix Label, an advanced labeling feature that converts the alphanumeric data from standard 3D printed labels into a data matrix code that can be applied to individual parts. These smart tags are smaller and can be read by conventional data matrix scanners. Machine-readable tags reduce human error and further automate the post-production process, which supports mass-customization.

Materialise offers multiple additional modules, which have been upgraded as part of the new release. The simulation module reduces the number of failed metal builds by showing potential build errors before they occur, without making users switch to a separate specialized application. Users of other 3D printing technologies can rely on the improved lap joint cut to easily assemble cut parts and generate e-Stage support in SG mode.

Materialise offers a range of software solutions to companies with varying 3D printing needs; an Essentials version for entry-level users; an Expert version for advanced data and build preparation; and an Enterprise offering to help industrial print factories manage their entire 3D printing process. Magics 23 is an extensive and easy-to-manage software suite for expert and enterprise users. Magics Essentials offers entry-level users a complete data preparation solution and is available online.

“With the introduction of Magics 23, we offer integrated automation features for metal 3D printing, including simulation and automatic support generation”, says Stefaan Motte, Vice President and General Manager of the Materialise software division. “This allows users to drive down cost by optimizing their machine operations and reducing the number of build fails, all within their trusted Magics environment.”

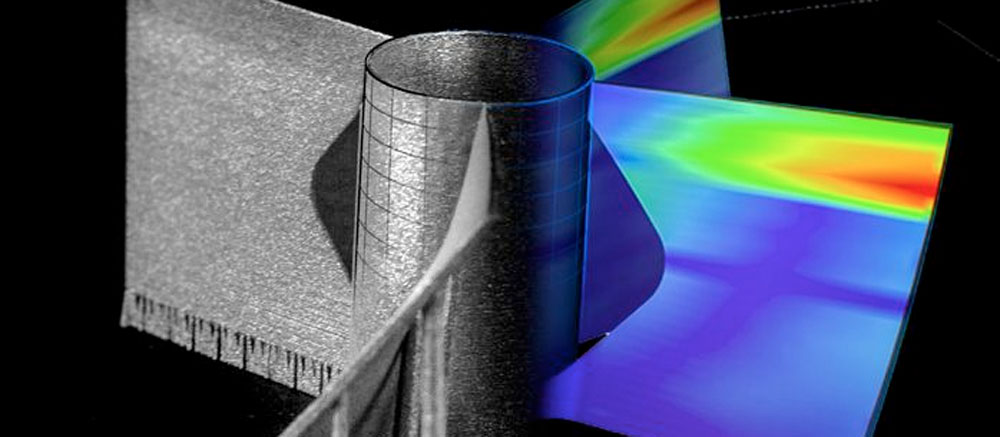

Materialise brings simulation to the production floor

The Materialise Magics Simulation module aims to make simulation easy to manage and accessible to a wider audience. The module is focused on optimizing the production process without the need for expert knowledge. In combination with Magics 23, it brings high-end simulation capabilities for 3D printing to the production floor. Users can apply simulation results directly to the support generation and orientation tools in their trusted Materialise Magics environment. It supports fast reruns on a standard workstation without the need for high-end processing power, and can also be used in combination with other computer-aided engineering (CAE) solutions for highly certified metal production. The module also includes an integrated calibration feature which guides users to the correct simulation settings for their metal machine.

With its simulation module, Materialise offers easier access to simulation for companies using 3D printing as an alternative manufacturing technology. For service bureaus that want to scale their operations, the module presents an opportunity to optimize their machine operations and get builds right the first time.

Integrated generation of support structures for metal 3D printing

With Magics 23, Materialise introduces improved automatic support generation for metal 3D printing. By integrating the new support generation module, users can automatically generate e-Stage support based on the defined profile; more easily edit, move or delete points; and receive immediate feedback on support volumes. Manually designing support structures for metal parts requires expert knowledge, is time consuming, and carries the risk of overusing expensive material. By generating the supports automatically, users can reduce data preparation time by 90 percent, cut support removal time by 50 percent and achieve a powder recuperation of nearly 100 percent, compared to manual support generation. The automated process also limits the risk of human error and related build crashes. This is especially relevant for metal 3D printing and the production of high-value, customizable metal components with complex geometries.

New materials broaden potential applications for prototyping and manufacturing

In addition to better, faster machines and increased automation, the development of new materials provides new impulses to the 3D printing industry. For manufacturers in the automotive, aerospace and consumer goods industries, new materials are a driver for accelerated adoption of 3D printing with the potential to create new and significant business opportunities. At Formnext, Materialise extends its 3D printing services offering with the introduction of three new materials: polypropylene (PP), one of the most commonly used production plastics; Taurus, a Stereolithography material aimed at automotive prototyping applications; and Inconel (IN718), a metal alloy used in the aerospace and automotive industries for both prototyping and end-part production.

Jurgen Laudus, Vice President Materialise Manufacturing, stated: “The automotive, aerospace and consumer goods industries have all been early adopters of 3D printing for prototyping applications. As the usage of 3D printing widens in scope and scale, we’re making strategic investments in expanding our service portfolio with materials that address the industries’ needs: whether it’s production-grade characteristics as in the case of PP and Inconel, or specific mechanical properties as in the case of Taurus.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.