In the aerospace industry weight can be translated directly into costs. So saving weight on rockets and satellites means cheaper transportation and more space for other equipment.

So of course additive manufacturing is used to build light weight structures out of strong materials like titanium. Materialise and Atos teamed up to develop specialised lightweight parts for aerospace.

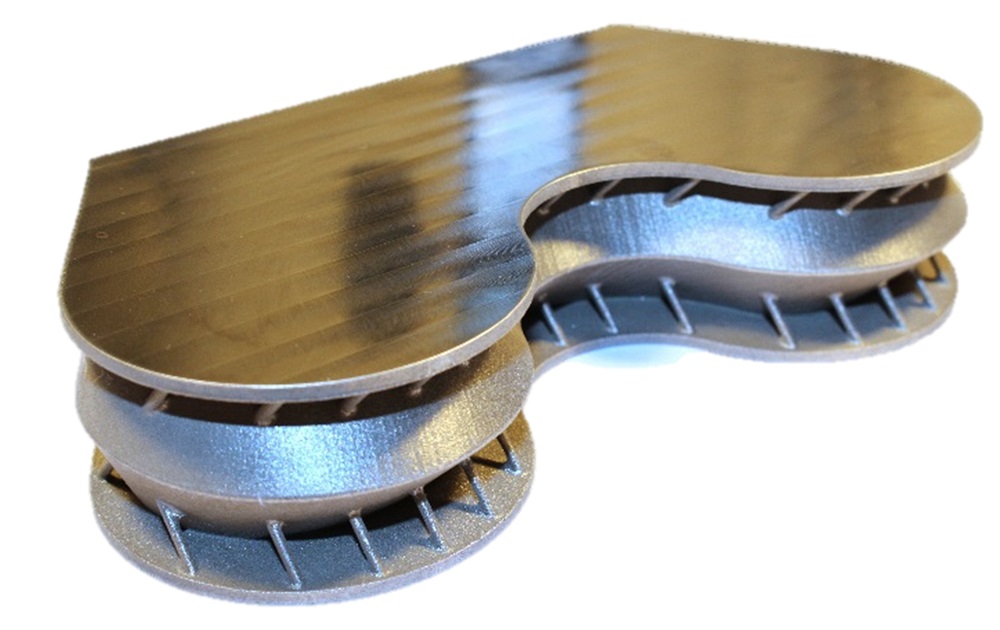

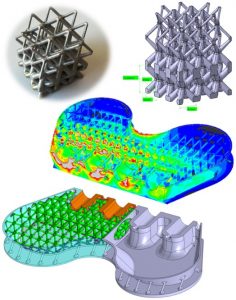

The part shown above is a insert which is used as a mounting point to attach devices to satellites. With 3D printing a sandwich structured insert was produced. The inside is filled with a very lightweight but strong honeycomb structure.

“The weight reduction will allow the increase of useful equipment to be used in satellites and result in considerable cost saving in each launch,” says Marta García-Cosío, mechanical engineering director at Atos Spain. “We are proud with this innovation. By creating this complex product in metal additive manufacturing in such a short time, Atos and Materialise are amongst the top of providers of Metal 3D Printing solutions.”

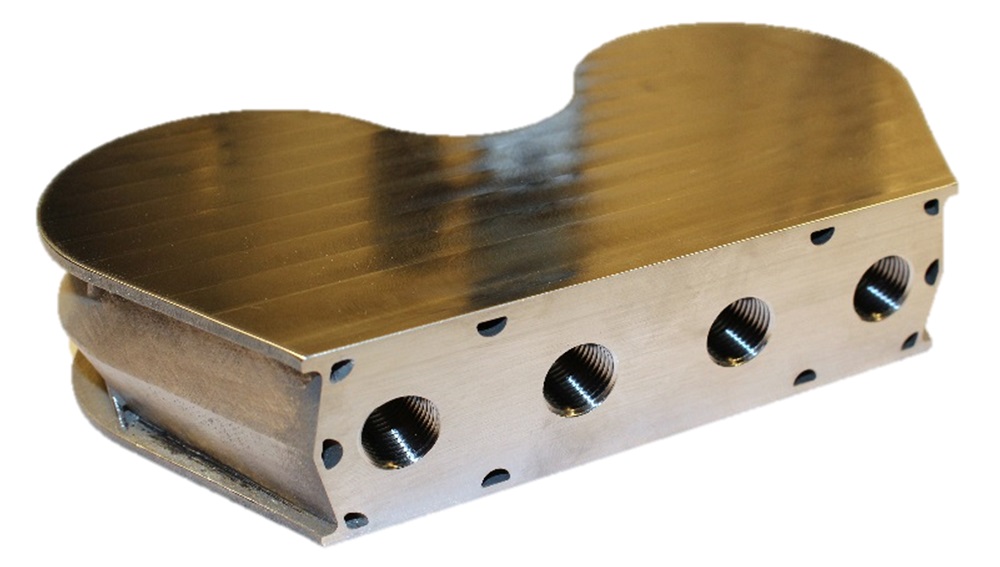

With conventional manufacturing the insert would be a solid titanium or alloy brick. Which not only uses more material but is  of course heavier. The weight could be reduced from 1.454 grams to 500 grams. The new design also reduced the thermo-elastic stress on the insert which improves the lifetime of the part.

of course heavier. The weight could be reduced from 1.454 grams to 500 grams. The new design also reduced the thermo-elastic stress on the insert which improves the lifetime of the part.

To design these parts Materialise 3-matic’s Lightweight Structures Module and Post-Topology Optimization was used. The parts were than manufactured with titanium (TiAl6V4) at Materialise´s Metal 3D Printing Factory in Bremen, Germany.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.