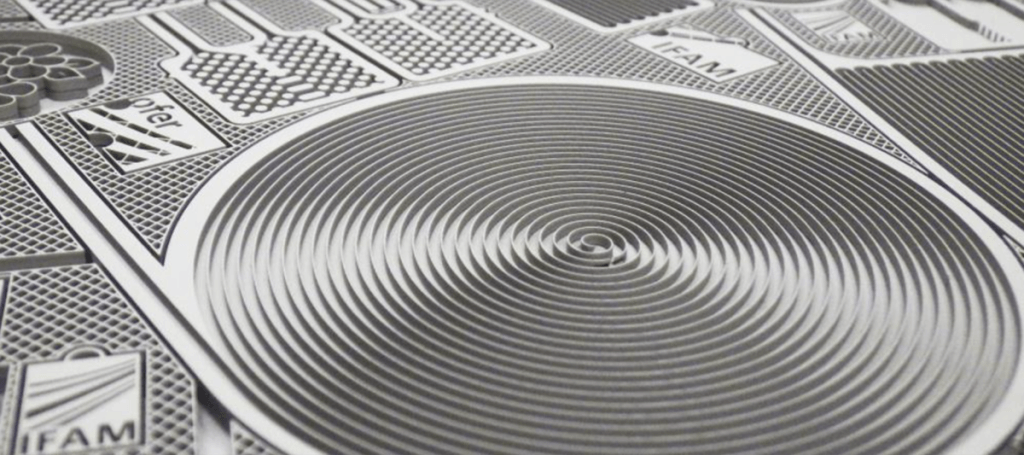

The IFAM (Fraunhofer Institute for Manufacturing Technology and Advanced Materials) in Dresden has developed a new way to create three-dimensional metal parts: With the help of stencils, metal powder is applied and then hardened.

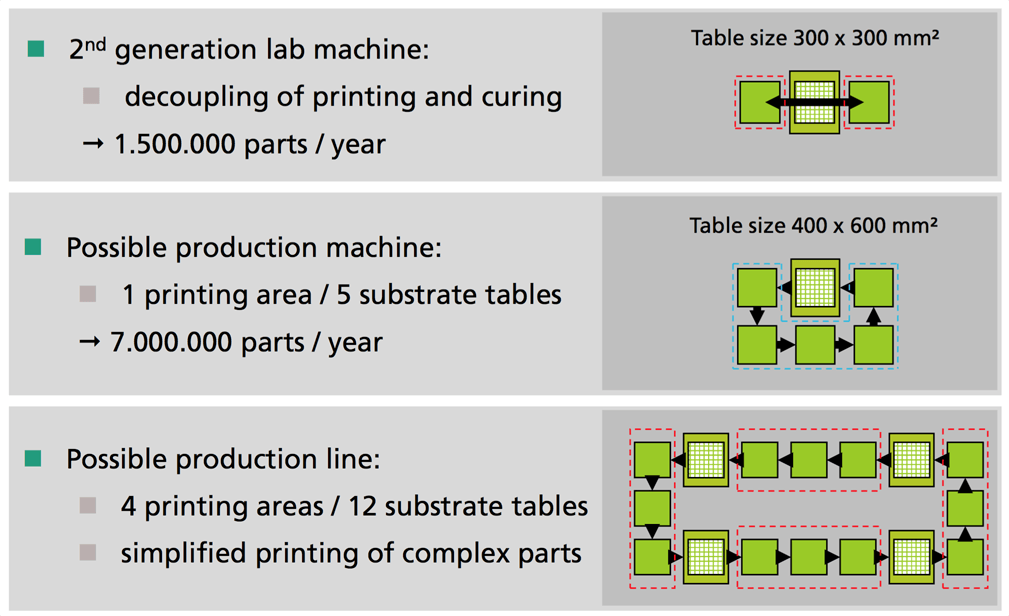

The new technique is a bit complicate but you can create parts with high mechanical quality and, if more machines are combined, even high production rates are possible (more than one million parts per year).

To create the new technique the Fraunhofer Institute uses some already existing techniques and combines them to a new one: After designing a 3D model, the screens for screen printing are created (one screen per layer). Then, metal powder combined with binder is pressed through the stencil (which is also called screen). Afterwards the object is hardened and then the next stencil is used to create the next metal layer. That process is redone until the object is finished.

With that an accuracy of 60 to 100 µm should be possible and the maximum printing height should be a couple of centimetres. More Information to this new printing technique is available on the website of the Fraunhofer Institute Dresden.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.