Researchers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a method to 3D print shock-absorbing materials that could not only make robots safer and more precise in their movements but also help improve the durability of drones, helmets, shoes and many other objects.

In a study that will be presented at the International Conference on Intelligent Robots and Systems in Korea next week, the team of researchers has come up with a technique to create “programmable viscoelastic material” (PVM). Using 3D printing technology, this method allows to program every single part of the object to the levels of stiffness and elasticity they require.

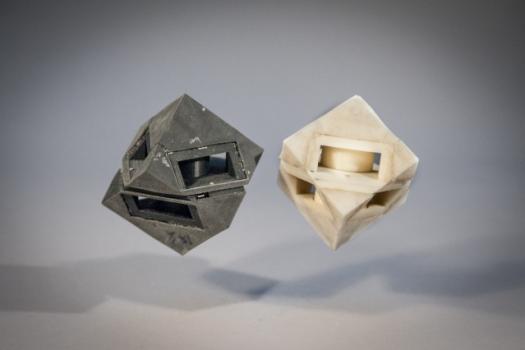

To put the developed method into practice, the team has 3D printed a cubic robot that moves by bouncing. With its shock-absorbing skins is uses only 1/250 the amount of energy it transfers to the ground.

Daniela Rus, CSAIL director and project lead explains: “That reduction makes all the difference for preventing a rotor from breaking off of a drone or a sensor from cracking when it hits the floor. These materials allow us to 3-D print robots with visco-elastic properties that can be inputted by the user at print-time as part of the fabrication process.”

Not only do PVMs dampen objects but they also allow printed objects such as the robot to land four times more precisely. This could be a fact particularly interesting for delivery drones.

While viscoelastic materials such as rubber and certain plastics are cheap and easily available, it is hard to customise objects using existing fabrication methods. 3D printing on the other hand opens up much more possibilities. The team used a solid, a liquid and a flexible rubber-like material to print the cube robot with its skins.

Hod Lipson, a professor of engineering at Columbia University and co-author of the paper titled “Fabricated: The New World of 3-D Printing” explains: “By combining multiple materials to achieve properties that are outside the range of the base material, this work pushes the envelope of what’s possible to print. On top of that, being able to do this in a single print-job raises the bar for additive manufacturing.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.