Nanoscribe presents IPX-M, the latest photopolymer printing material for high-throughput macro printing with print volumes of up to 30 cubic centimeters in one pass.

IPX-M is specifically designed for Quantum X systems and best suited to exploit the full design freedom for 3D printing complex shapes with high shape accuracy and large volumes up to the centimeter scale. The new material expands the IPX photopolymer printing materials series that has been developed to benefit from the printing speed, precision and performance of the industry-proven Quantum X platform.

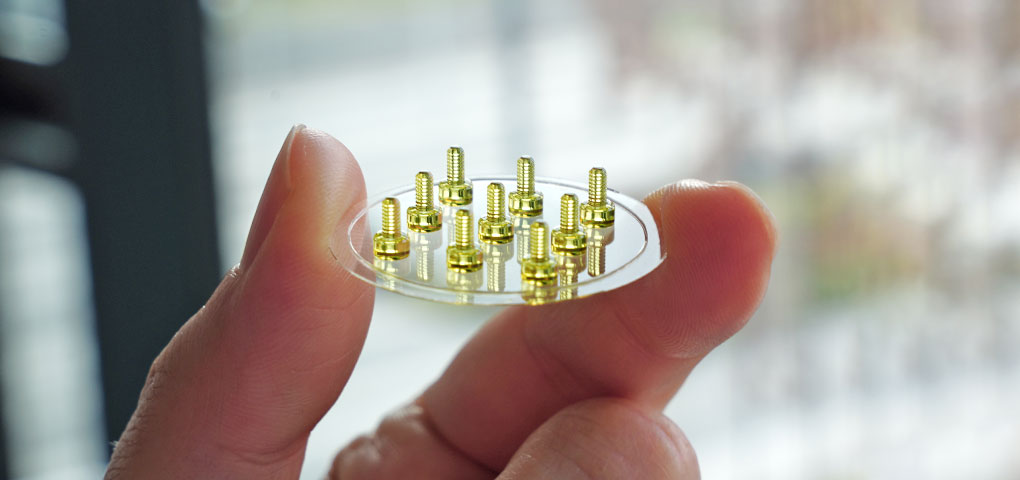

Two-Photon Polymerization-based (2PP) microfabrication with nanoscale features is associated with the manufacturing of nano-, micro- and mesoscale structures. Now, Nanoscribe introduces the new IPX-M printing material to close the gap of high-throughput macroscale printing of millimeter- and centimeter-scale objects. The new photopolymer exploits the performance, print speed and precision of Quantum X systems to fabricate complex 3D shapes with high shape accuracy. Thus, Nanoscribe’s advances in hardware, software and materials development offer a new and complete solution that pushes the boundaries in 2PP-based fabrication to fulfill the market needs for macroscale printing millimeter- and centimeter-scale objects.

High-performance microfabrication

The industry-proven Quantum X platform offers high-precision 2PP-based 3D printing and moreover the innovative Two-Photon Grayscale Lithography technology for 2.5D microfabrication. The new IPX photoresin series of photopolymer printing materials has been specifically designed to exploit the best performance achievable with the platform. Optimized for different structure qualities and processes, IPX Photoresins fulfill various market needs in microfabrication.

“IPX Photoresins enable true high-performance printing with maximum possible throughput while maintaining best precision with Quantum X systems“, Dr. Alexander Quick, Head of Materials Development and Production at Nanoscribe explains.

High-throughput macroscale printing

IPX-S and IPX-Q are designed for printing mesoscale structures with micrometer precision using Two-Photon Grayscale Lithography and Two-Photon Polymerization correspondingly. To close the gap of macroscale printing with high-resolution 2PP-based 3D printing, Quantum X systems combined with the new IPX-M are able to fabricate print volumes up to 30 cm³ in one pass.

“The new IPX-M stands for macroscale printing and offers highest throughput for printing parts in the millimeter and centimeter scale.” Alexander Quick adds.

The new printing material offers full design freedom for 3D objects with arbitrary shapes, high aspect ratios, and large volumes up to the centimeter scale.

Towards rapid prototyping and batch production

What are the applications of this new material? Based on its characteristics and high throughput for macroscale printing, IPX-M is the best choice for rapid prototyping and small scale fabrication. Print high-precision parts and objects on the millimeter- and centimeter-scales to validate new product designs. The key of this new high-throughput printing material are short print times required for rapid prototyping and serial fabrication by batch production.

Find out more about Nanoscribe at nanoscribe.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.