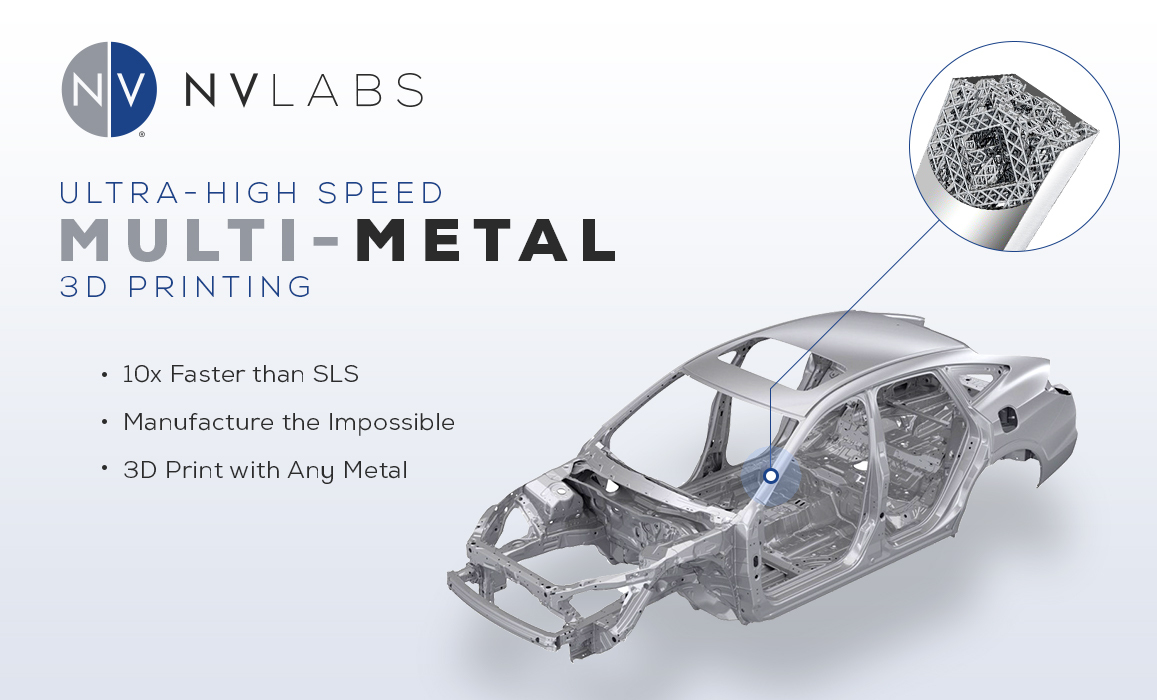

3D printing company NVBOTS has established NVLABS to push the limits of ultra-high speed, multi-material 3D printing. They want to support other companies to capitalise on opportunities related to 3D printing metals, including stainless steel, titanium, nickel, copper nickel, aluminum, zirconium, silver and palladium.

NVBOTS also announced that metallurgy expert Dr. Paul Burke was appointed Chief Research Officer, leading the R&D department of NVLABS. He will oversee all NVLABS-sponsored projects and future innovations based on the NVBOTS patented technology platforms.

NVBOTS CEO AJ Perez said: “As NVBOTS has evolved, our core focus has always been around a three-part evolution: education, innovation and commercialisation. Through the establishment of NVLABS and bringing on Dr. Paul Burke, we are breaking new ground in enterprise 3D printing, through unmatched multi-metal printing capabilities, allowing companies on a global scale to commercialize their innovations in ways never before thought possible.”

Companies collaborating with NVLABS will be able to 3D print at reduced costs over 10x faster than existing solutions and benefit from innovations, based on accelerated metals testing and engineering of designs which will dramatically improve efficiencies related to assembly and performance.

“With NVLABS, the company is set to take things to an entirely new level, granting companies access to state-of-the-art automation and ultra-high speed, multi-metal printing capabilities that will allow them to cost-effectively manufacture and scale, in ways only imagined – until now,” Dr. Burke said. “I am proud to be part of such a well-respected and progressive company, and I look forward to making a difference in the world through our efforts.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.