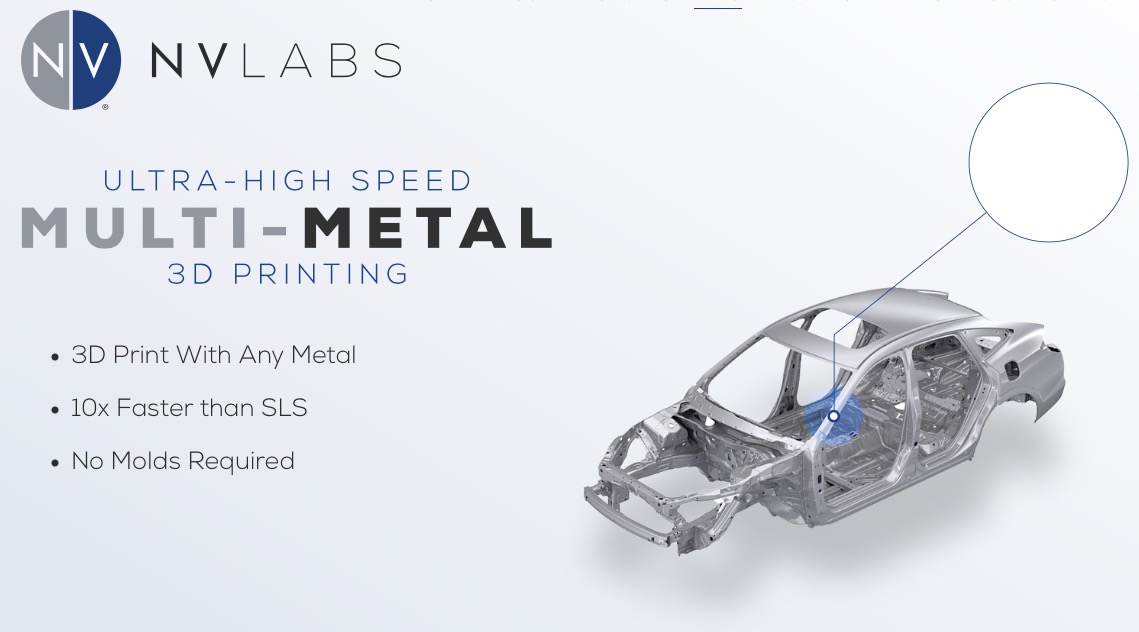

Following the launch of NVLABS, established NVBOTS earlier this year, the 3D printing company now announces access to their high-speed multi-metal 3D printing technology for commercial use through its Alpha Program.

The Program is targeted at companies that aim at commercialising their innovations through fast multi-metal 3D printing technology.

“At our core, NVBOTS is driven to turn ideas into realities, challenge the status quo and deliver on the impossible,” said NVBOTS CEO AJ Perez. “Through the introduction of our ultra-high speed, multi-metal 3D printing technology, we are doing just that. And not only are we disrupting the 3D printing industry, we are solving the toughest problems in additional markets, such as the metal castings sector, which will have a significant impact on medical, automotive and aerospace industries, among others.”

NVLAB’s proprietary technology allows for 3D printing with multiple metals in the same build at a speed 10x faster than Selective Laser Sintering (SLS) and at significant cost advantage. Companies would therefore benefit from reduced labor costs along with accelerated metals testing and engineering of designs. Moreover, they would be able to improve efficiencies related to assembly and performance.

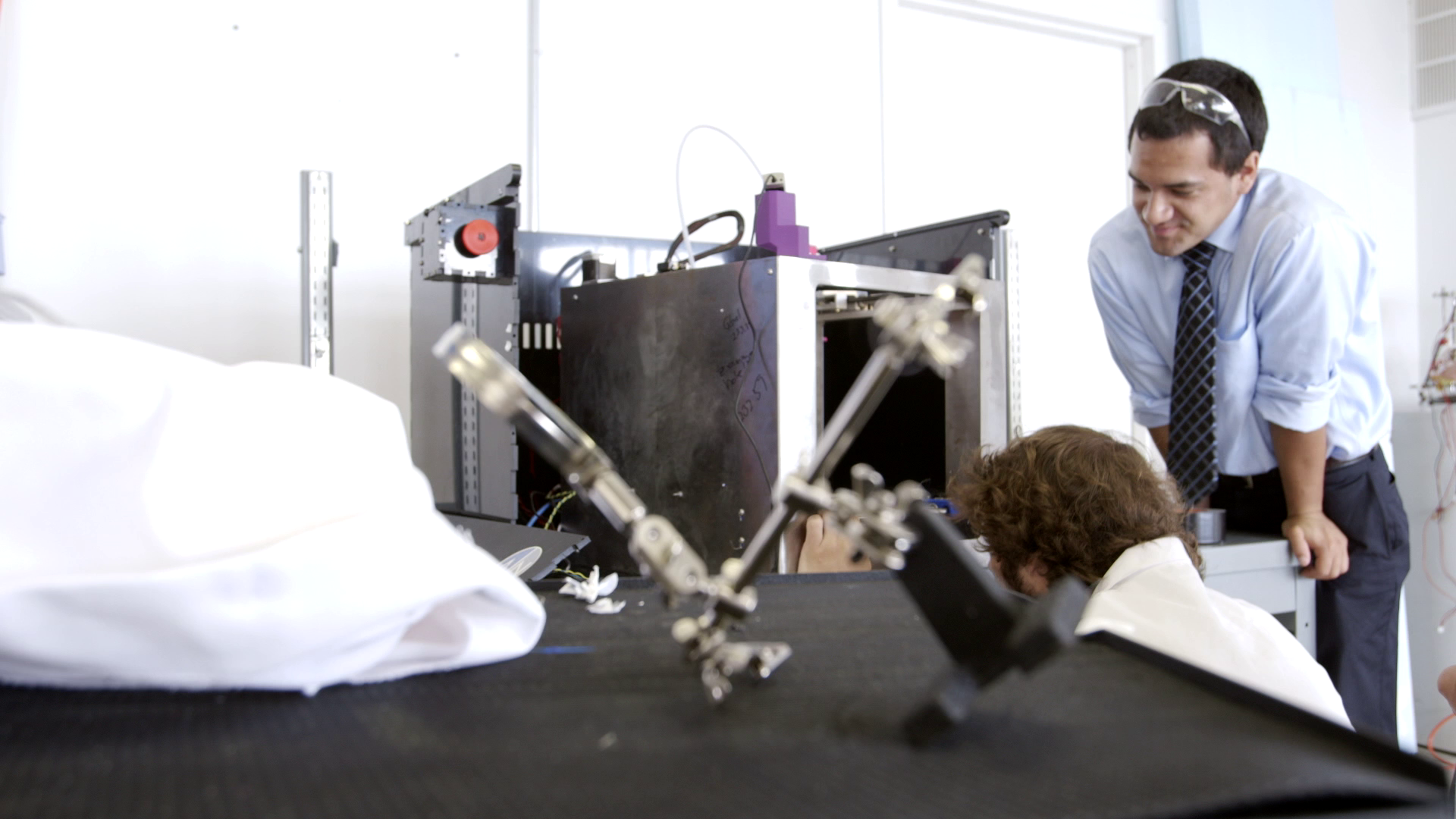

NVLABS Chief Research Officer Paul Burke stated:“NVBOTS is breaking entirely new ground by bringing together a powerful combination of patented technology, with a level of 3D printing and metallurgy expertise unmatched in the industry. Any company prioritizing on the ability to cost-effectively manufacture and scale will benefit from being part of the NVLABS Alpha Program.”

Currently, their list of printable metals includes: platinum, zirconium, gold, silver, tantalum, silicon bronze, platinum iridium,aluminium, nickel, monel, stainless steel, copper nickel, hafnium, nickel titanium, titanium, tin, zinc, lead, palladium, molybdenum and niobium.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.