Open Additive, LLC, and Addiguru, LLC announced an agreement to provide Addiguru’s Laser Powder Bed Fusion (LPBF) analysis software using layer-wise optical camera data as a plugin to Open Additive’s AMSENSE multi-sensor data collection and analysis platform.

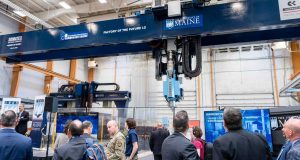

To date, the proliferation of metal additive manufacturing (AM) across industries has been hindered by the substantial added costs of process development, failed builds, and post-build inspections. A variety of machine-specific and machine-independent in-situ monitoring technologies have been introduced at various technology readiness levels in recent years to address process control needs. While other commercial offerings in this space tend to be very expensive, highly proprietary, or both, Open Additive and Addiguru have each taken the approach toward more affordable and versatile product solutions.

For AM process monitoring, Open Additive has commercialized its AMSENSE multi-sensor data collection and analysis platform, first delivered in beta form to customers in 2018. Over the last several years, the open-architecture suite has been demonstrated as an add-on capability on a variety of industrial LPBF systems to collect data for research, part maturation, and part serial production. AMSENSE is a modular hardware/software platform with the ability to integrate various sensors and analytics as needed. In the last few years, Open Additive has commercially sold various configurations for use on its own PANDA system as well as other brands of machines.

Addiguru provides real-time monitoring solutions for Additive Manufacturing processes using affordable and practical solutions. Addiguru provides process insights and reduced production costs for AM service bureaus and other industry users. The company’s software uses computer vision, artificial intelligence (AI), and machine learning (ML) methods to identify critical process errors and send real-time alerts to save production time and costs. Addiguru has worked with several partners to demonstrate its process monitoring capabilities across several important industrial machines. The software has been commercialized and has multiple installs in the industry.

Open Additive and Addiguru are excited to collaborate and provide AMSENSE with Addiguru’s Recoater Plugin to LPBF users. AMSENSE captures the layer-by-layer data of the LPBF real-time process build, which when joined with Addiguru’s Recoater Plugin, processes that data to provide a layer-by-layer recoat analytical interpretation of the captured data. Together these two capabilities represent the state-of-the-art in real-time additive manufacturing system monitoring and process controls.

Dr. Thomas Spears, AMSENSE lead developer shared that the “Recoater plugin when combined with AMSENSE provides unparalleled insights into an additive manufacturing system’s performance, along with the most comprehensive insights into the as-built characteristics of an additively manufactured part.”

Open Additive’s Managing Member, Joe Sciabica shared, “I am pleased with the Addiguru collaboration on AMSENSE and look forward to working closely with Addiguru to bring this new analytic to market, especially with the actionable information that Addiguru’s Recoater Plugin will provide to additive manufacturing systems users and researchers alike.”

“Addiguru recognizes the high added costs of part development and production due to lack of useful process insights and controls,” added Addiguru’s founder, Shuchi “SK” Khurana, “and we’re excited to work with Open Additive to bring practical and affordable solutions to the metal additive manufacturing industry to address this problem.”

For more information about Open Additive, visit www.openadditive.com.

For more information about Addiguru, visit www.addiguru.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.