A research team explored the capabilities of Fused Filament Fabrication (FFF) to create medical implants. They examined the effects of infill density, and patterns of 3d printed Polyether ether ketone (PEEK) and Polymethyl methacrylate (PMMA) for cranial implants. Cranial implants require many characteristics including; biocompatibility, durability, inertness, intraoperative workability, long-time stability, stabilizability and strength.

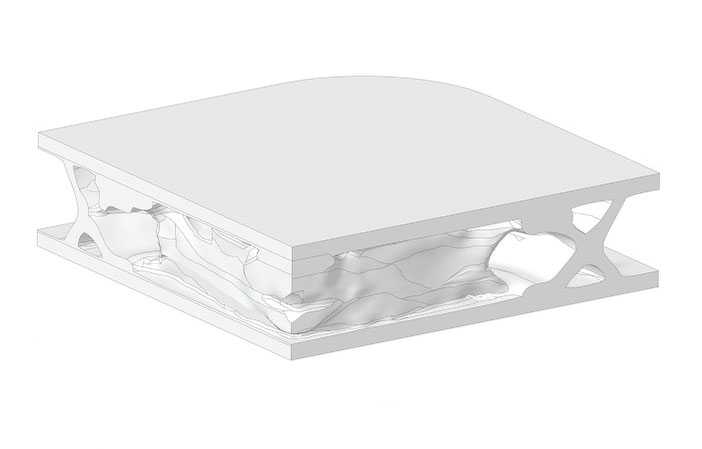

The team tested PEEK and PMMA separately and in combination in the form of a “sandwich structure”.

The team published their tests under the title: ‘Impact Optimization of 3D Printed Poly(methyl methacrylate) for Cranial Implants,’ and concluded that “both thermoplastics are inert, biocompatible, and reveal adequate mechanical properties in order to replace bone. PEEK outpaces PMMA in terms of strength, stiffness, and durability. In contrast, PMMA is easily obtainable and affordable”. In terms of the sandwich structures, they summarized that “all tests, regardless of infill density and structure, show a step‐wise failure behaviour, which can be seen as several peaks in the force-displacement curves. This is a quite common phenomenon in sandwich structures since the fracture behaviour of the surface layers and the core material is quite different.”.

The team then improved the stiffness and energy absorption of PMMA samples by varying the infill rates from 50% up to 100% and concluded that “ED in combination with the dynamic stiffness or deformation reached up to this point represents a very critical parameter regarding the designing process of implants. If a high tolerated force level in relation to the absorbed energy is desired, 3D‐HC internal structures at an infill density of 70% and rectilinear structures with an infill density of 100% are recommended at this time.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.